At the heart of every diesel engine is an injection pump which can take ordinary fuel and pressurize it to incredible levels, sometimes close to 30,000 psi. It uses this extreme pressure to force the fuel directly into the combustion chamber as the piston approaches top dead center, and the superheated air inside the cylinder ignites the diesel fuel and turns it into mountains of horsepower and torque. While it may seem like a pretty simple piece of equipment, in reality an injection pump in a common rail diesel engine is very sophisticated and must be constructed with the tightest tolerances. 2021 marks the 20th anniversary of common rail diesel injection in pickup trucks (started by the Duramax in 2001) and throughout that time one supplier has held an almost exclusive monopoly across all three pickup brands when it comes to building high pressure pumps: Bosch.

You might’ve heard the name from their home appliance line or even their power tools, but they are also an OEM Supplier for many automotive parts, and injection pumps are one thing they make a TON of. In fact, Bosch has been making injection pumps for Cummins and other industrial diesel engines long before they started putting the 6BT in the Ram 2500 and 3500, but their pump lineup in pickups has included the VE, P7100, VP44, and for 15 years, the CP3. The high pressure CP3 saw the longest run of the bunch, going from 2003 until 2018, and Ram owners enjoyed one of the most reliable fuel systems in the common rail category, avoiding some of the problems that plagued the CP4.2 injection pump (also made by Bosch) used in the LML Duramax and the 6.7 Powerstroke. But that 15-year run came to an end in 2019 when Ram made the somewhat questionable decision to switch the injection pump to the CP4.2. Diesel owners in the know were somewhat frustrated with this decision, but to understand why, we need to look at the track record of each pump.

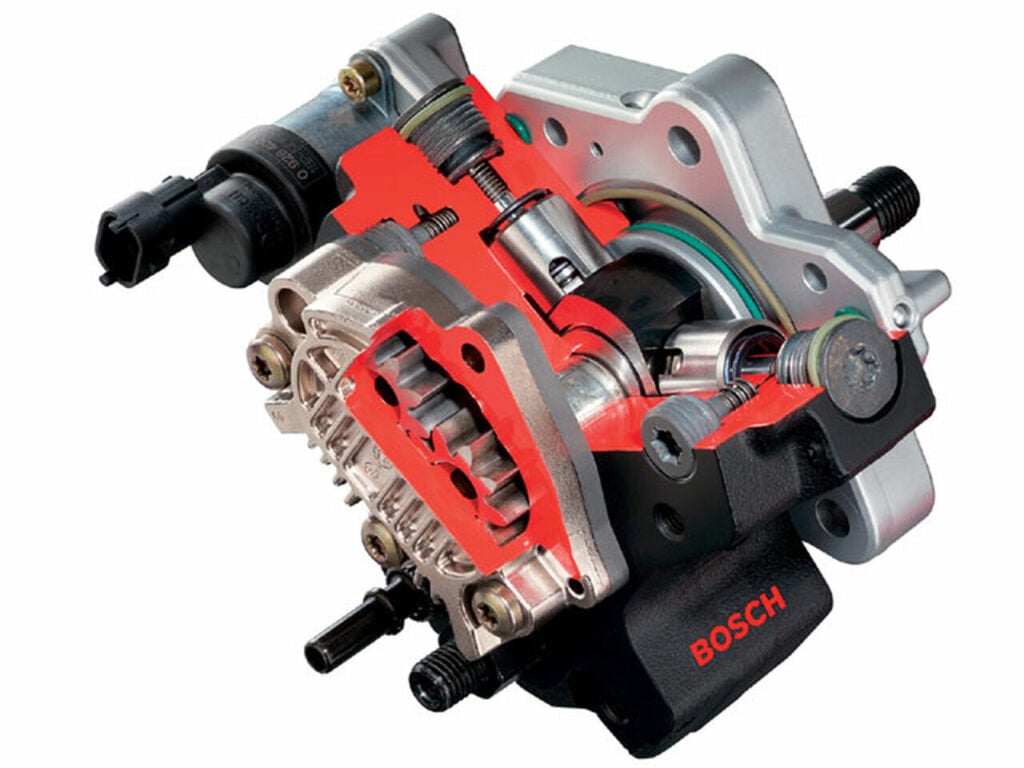

What Makes the CP3 Great

GM was the first to use the CP3 in a pickup application with the LB7 Duramax in 2001, and just two years later in ’03, the Cummins engine in Dodge Rams also started using the Bosch pump, with the only functional difference being Dodge also utilized a lift pump in the tank, where GM relied on the gerotor pump built into the back of the CP3 to draw fuel from the tank and bring it up to the engine. Each CP3 had slight tweaks in its design depending on whether it was intended for a Cummins or a Duramax application, but either version was very reliable and could support roughly 550whp in a high performance application. Longevity of the pump depends on a lot of factors like fuel filter service interval and quality of fuel running through it, but on average you could expect a CP3 to last anywhere from 150,000 to over half a million miles. When it is on its way out, the first sign of trouble the driver might notice could be a lack of power or drop in fuel mileage, but both symptoms are attributed to the pump not being able to keep up with the fuel pressure being requested by the ECM. Additionally, you might also notice a check engine light indicating low rail pressure or a “service fuel filter” reminder pop up in the message center.

Thankfully, when the CP3 injection pump does fail, there are plenty of warning signs and it usually won’t leave you stranded on the side of the road. Even though it’s at the heart of your injection system, when a CP3 does fail there is no other collateral damage, and it’s a simple job to fix. All you’ve got to do is unbolt the old pump, install a new one, throw in a new fuel filter, and you’re back on the road in no time. Stock replacement CP3 pumps are readily available, but if your truck has been modified at all, this is also a good opportunity to throw in a modified version of the pump that can support higher horsepower. One drawback of the stock CP3 is a fuel restriction that occurs at 3,000 RPM and above, but for nearly the same price as a stock replacement, you could choose the Fleece Performance CP3K. It’s a stock displacement pump, but its internal circuitry has been tweaked to allow full fuel flow at any RPM which lets you take full advantage of your performance tune. If you’re chasing a much higher power number, you could instead upgrade to a Fleece PowerFlo 750 10mm Stroker pump. Because a CP3 uses what is essentially a flat tappet camshaft to actuate the pumping mechanism, you can increase the lift of the cam, and therefore increase the volume of fuel the pump produces, and ultimately support more horsepower. A 10mm CP3 for example supplies enough fuel for roughly 750 horsepower, but pumps are also offered with 12 and 14mm strokes for extreme performance builds, and of course you can even run multiple injection pumps for virtually unlimited fuel flow.

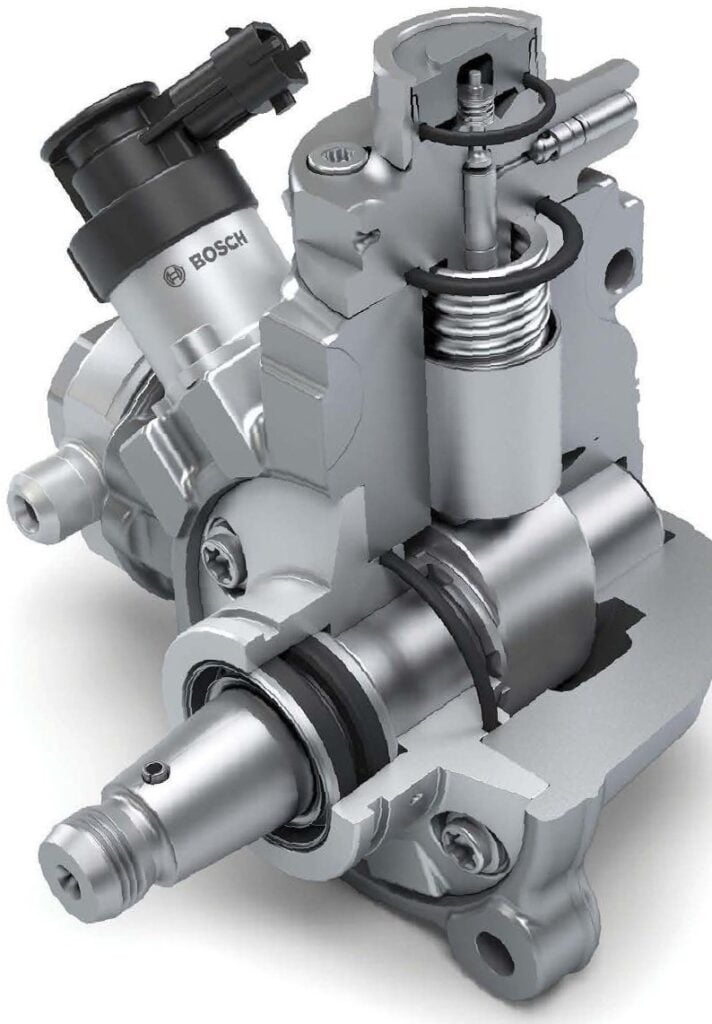

What Makes the CP4 Awful

There are many reasons why a manufacturer would choose to move away from an injection pump with such a good track record, but in 2011, both GM and Ford chose to install the Bosch CP4.2 onto their newest engines, the 6.7 Powerstroke V8 and the 6.6 LML Duramax. Some speculate the decision was made due to the lighter aluminum housing in an effort to save a few pounds, and others say it was a cost saving effort. Another explanation I’ve heard that actually makes sense attributes the decision to go with the CP4 because of its increased pressure capability compared to the CP3, which helps better atomize fuel and reduce emissions. As we all know, manufacturers are under ever increasing pressure from regulatory agencies to reduce the emission output and increase the fuel mileage of their trucks, and since the CP4.2 is rated to produce a maximum of 29,000 psi which is about 3,000 more than what you could expect from a CP3 pump, the decision starts to make sense because diesel engines run cleaner at a higher injection pressure.

Almost immediately in 2011, you started hearing horror stories from both Duramax and Powerstroke owners regarding their failed fuel system. Owners could be driving along in their couple month old Denali LML, and suddenly the engine loses power, a check engine light comes on, and within a minute or two, the engine shuts down. Once the engine stops no amount of cranking will start it up again, and the truck will have to get towed to the dealership. The usual diagnosis is a failed CP4, but to get the truck back on the road, its gonna take a lot more parts than just a high-pressure pump. Unlike its predecessor, whenever a CP4 fails, it sends metal shavings and debris into the rest of the fuel system, which contaminates the rails, high pressure lines, injectors, overflow valve, and return lines. Sadly, these components are too intricate to simply rinse out and reuse, so after a pump failure you are forced to replace the entire high pressure fuel system. Luckily, for most owners, the first CP4 failure is covered under the powertrain warranty, but if you were outside of your warranty period, you could expect a repair bill between $7,000 to $10,000 depending on who does the work.

It’s said the culprit is the lesser quality fuel we have in North America, mainly due to its lack of lubrication compared to European diesel, but also a small amount of water in the fuel supply can wreak havoc with the CP4, and other times the roller lifter inside the pump will randomly decide to turn sideways, and the wheel will cut a groove into the pump’s camshaft. Granted, the true number of CP4 failures is likely a bit inflated due to internet discussion forums, but it is a proven fact the CP4 isn’t as reliable as the older CP3.

Ram Makes the Switch?

I’m almost positive the engineering team at Ram had some intense debates when it came to the decision to switch to the CP4.2 pump for the 2019 model year, and certainly there was at least one who pointed out the massive headaches and warranty claims the CP4 caused GM and Ford eight years earlier. Regardless of what went on in the board meeting that day, the decision was handed down, and the 15-year marriage between Cummins and the CP3 was over. Sure, the 2019 HO Cummins boasted a first-ever 1,000 lb.ft. torque rating which was impressive, but at what cost? You can probably guess what happened next… more CP4 failures, and in the exact same way as they fail in the LML Duramax and 6.7 Powerstroke. Sudden loss of power, the engine dies, bad news from the shop, and a complete fuel system replacement is required, and in some cases, Cummins just replaces the ENTIRE engine.

Once again, there must’ve been some logical reasons why they made the switch, and I’m sure the number of actual failures may be slightly exaggerated, but the fact is there have been many documented failures in 2019 and 2020 6.7 Cummins, with some occuring with as little as 7,000 miles on the odometer. Luckily though, it appears Ram learned their lesson a lot quicker than GM and executed what is probably the quickest redesign in automotive history, and two short years after the CP4 made its debut on a Cummins, it was gone again. That’s right, 2021 model year 6.7 Cummins trucks have switched injection pumps again, going right back to the CP3. Thankfully it was a no compromises situation, and instead of reverting to the 2018 horsepower levels, things were bumped up even further to 420hp and a class leading 1,075 lb.ft. of torque, all while meeting emissions requirements. Hopefully this move pays off and puts Ram back at the top of the heap when it comes to reliability for a long time to come.

What to do with your 2019-2020 Ram?

More than likely, if you do own a CP4 powered Ram, it’s still covered by its 100,000-mile powertrain warranty, so unless you’ve modified your truck, any CP4 failure should be repaired at no cost to you, but are there any steps you can take to reduce or even eliminate the chance of a pump failing?

One surefire way to extend the life of your CP4 is feeding it a steady supply of clean fuel, so changing your fuel filters at their scheduled interval or even a bit sooner is a great first step. Once that’s taken care of, the next measure you can take is to add some extra lubrication into the fuel system with an additive like F-Bomb. It simply gets poured into the fuel tank with each fill up and helps protect the moving parts inside the CP4 with a little extra lubricity, but there will also be other side effects from F-Bomb like better fuel mileage and more horsepower. From there, you’re left with two options if you’re driving a 2019 or 2020 Ram and don’t want to tempt fate: change the pump or change the truck.

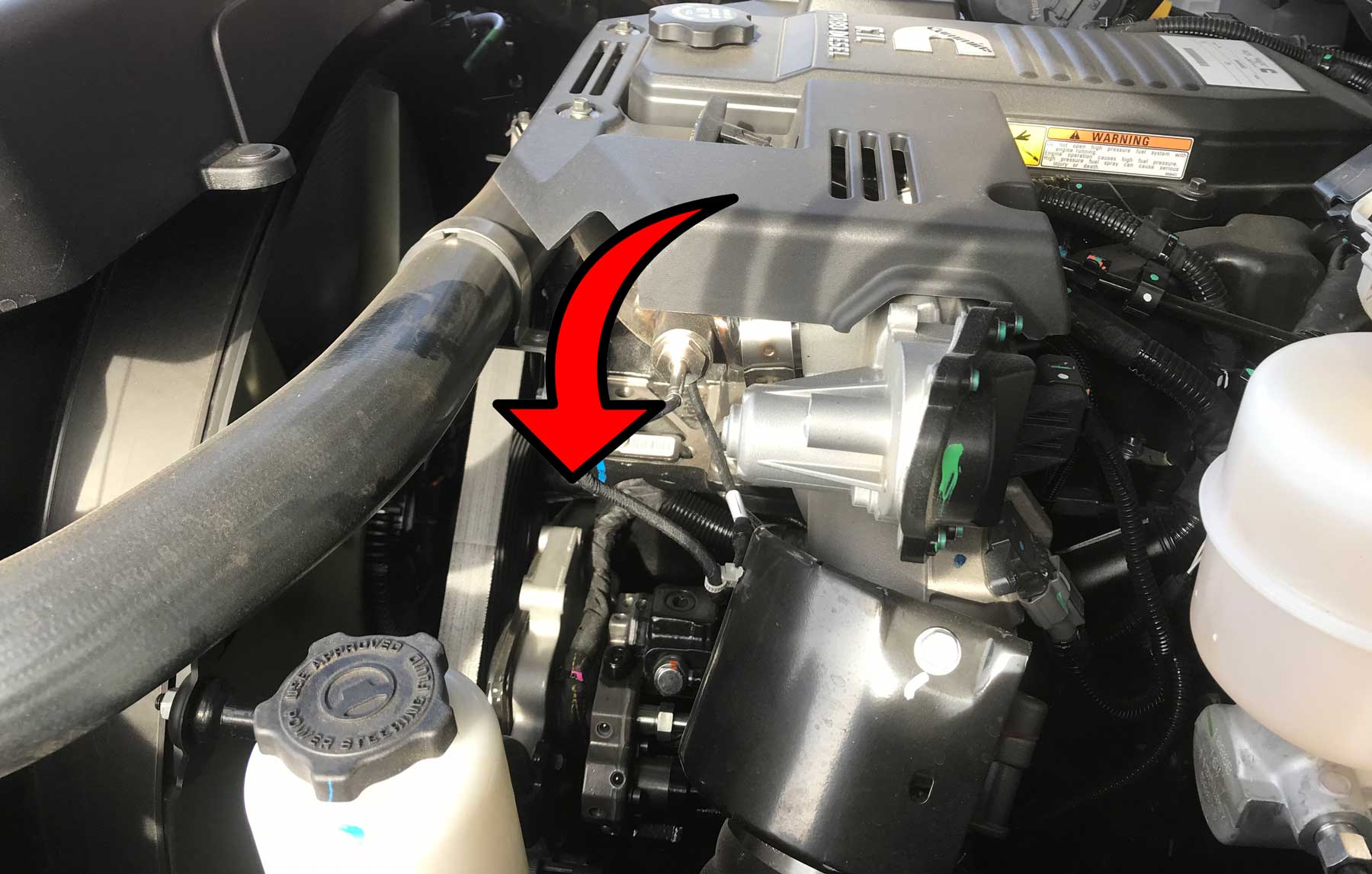

While trading your almost new truck in might be a smart move for some, what if you already have customized the rest of your Ram and like the one you have? Thankfully, almost as soon as CP4 powered Rams began hitting the streets, companies like Industrial Injection began marketing a kit that allows you to convert back to the much more reliable CP3. Their kit adapts the ’19 and ’20 6.7 Cummins engine to the CP3 pump, which means you get new high-pressure lines, the necessary hardware to attach the CP3, along with the wiring so you can plug in the new pump without any tuning required. Industrial’s kit is compatible with all emissions systems, and the included pump is a 10mm stroker that produces the same pressures as the CP4, but also supports more horsepower than stock.

Déjà Vu All Over Again

They say those who do not learn from history are doomed to repeat it, and it appears that this adage still holds true today. While it did hurt the feelings of many loyal Ram owners when they made the decision to swap to the CP4 in 2019, luckily Ram quickly corrected their mistakes and got back on the right track with the CP3 pump. As the horsepower wars continue to escalate in the diesel segment, soon there will be a need for an even more capable injection pump, but until then it appears the CP3 is still the pump of choice for Cummins. It’s worth noting that Ford still uses the CP4 to this day in the 6.7 Powerstroke, but its rumored sometime around 2015 they developed a special internal coating to reduce friction and help the CP4 last a lot longer, and it appears to be working. As far as GM is concerned, they parted ways with Bosch after the LML/CP4 fiasco and starting in 2017 with the L5P, Denso is now the supplier of both the HP4 injection pump and injectors. If you boil it all down, the CP4 isn’t necessarily the worst injection pump in history, and many have been reported to last several hundred thousand miles, but it is certainly much more sensitive compared to the CP3.

Hoe easy Can the L5P Denso pump be adapted to an older 2003 Duramax

Wow! Very interesting, I work on mostly Cat Heavy equipment & they also had a big problem with there rail pumps on the 9.3 engine, they would fail so bad and contaminate the entire engine for a complete tear down! (Perkins system?)

The roller lifter would turn, taking out the cam etc. throwing metal in the engine.

The cam lifter clips would brake also spinning the roller lifter thus taking out the cam! What the hell people! You want to know how to retain a roller lifter look at the racing gasser guys! Of course there not pushing 30,000 PSI of fuel?

All in all i am old school- P-pump baby! Full fuel, complete oink!!

Lattest new

Ram just keeps making dumb mistakes, not only does my 2019 have the CP4 , but it has a bigger engine than my 2006, a higher tow rating but a smaller fuel tank! I mean come on guys these are just dumb decisions that really p—- off people after they buy then find out!

I am no diesel mechanic/technician or automotive engineer. But, as with many things, build it rugged and reliable and dependable and everyone wins. Then, stay with what works and if the “feds” are pushing emission standards improvement re-design the component to assure reliability. Never cut corners. Build it “right!”

What are your thoughts about running dual CP3’s? If a single can technically support 550 RWHP, would it be better to run an upgraded single or run duals when close to the 550 mark? Pros and cons for both set-ups?

Hi its interessant updates ut what pampoen can be used to replace the vp44 pump in the 2002 Isuzu 300 tdi lx