S&S Diesel Motorsport stands at the forefront of modern diesel injection and vehicle control technologies, boasting a legacy of unparalleled expertise in OE diesel injection and engine development. With a commitment to innovation and quality, S&S Diesel Motorsport crafts cutting-edge products tailored for top-tier competition and CARB-compliant street applications. Their products are meticulously engineered using the industry’s finest components, rigorously tested on state-of-the-art equipment, and brought to life by the world’s foremost experts in the field.

Their custom injector testing equipment, meticulously modified in-house, sets the gold standard for validation. Capable of measuring injection rate shape and the complete profile of five injection events per simulated combustion cycle simultaneously, their fuel lab surpasses OEM capabilities. From testing all sizes and models of high-pressure fuel pumps to pushing the limits with their modified test bench spinning pumps at speeds exceeding 6,200 RPM, they ensure durability even in the most demanding high-rpm racing environments.

Trusted by industry giants like Cummins, GM/Duramax, and PACCAR, S&S Diesel Motorsport’s engineers offer unparalleled consulting services, backed by years of OE fuel system and engine development experience. Leveraging their extensive experience in OE-level engine development, their engineers rigorously test common rail diesel engine platforms, gathering critical performance data with their advanced engine dynamometer cell. Beyond fuel systems, they provide turn-key engine control packages utilizing cutting-edge electronics and full support from their calibration experts.

From 1.5L to 19L engines, they’ve successfully developed common-rail diesel fuel systems for a wide array of sizes and applications. Anticipating the evolving automotive aftermarket landscape, they lead the charge towards CARB-compliant products focused on solving durability challenges. Their solutions, such as the 50 State LML Duramax CP3 Conversion Kit, Gen2 6.7 Power Stroke Disaster Prevention Kit, and SAC00 LB7 Duramax Injectors, exemplify their dedication to innovation and compliance.

At S&S Diesel Motorsport, they don’t just set the bar — they raise it. With unrivaled expertise, cutting-edge technology, and an unwavering commitment to excellence, they continue to push the boundaries of diesel performance and reliability.

TOP 3 TRENDING ITEMS:

Ford 6.7L Power Stroke CP4 To DCR Pump Conversion

We’re going to discuss the most popular items that S&S Diesel Motorsport has to offer. While thinking about this list, there is one specific item that cannot be missed, the DCR Pump Conversion for the 6.7L Power Stroke. The CP4 high-pressure fuel pump in 2011 to current Ford Super Duty diesel trucks has garnered a notorious reputation for its sudden failures, resulting in unexpected power loss and costly damage to the high-pressure fuel system. The dire consequences of these failures extend beyond inconvenience, often leading to roadside breakdowns and repair bills that can soar beyond $10,000. Recalls and lawsuits targeting various auto manufacturers utilizing the CP4 fuel pump underscore its unreliability.

In response to this pressing issue, S&S Diesel Motorsport, renowned experts in common rail diesel injection, joined forces with PurePower Technologies, Inc., the aftermarket division of esteemed fuel system manufacturer Stanadyne, to tackle the seemingly insurmountable challenge. Together, they have engineered a groundbreaking solution to address the CP4 fuel pump woes plaguing Ford Super Duty trucks equipped with the 6.7L Power Stroke diesel engine.

The collaborative effort of the S&S Diesel Motorsport and PurePower engineering teams has yielded a game-changing innovation: the S&S Diesel Motorsport Ford 6.7L CP4 to DCR Pump Conversion. This revolutionary plug-and-play replacement pump offers unparalleled durability while seamlessly integrating with OE fit and function, ensuring peace of mind for Ford truck owners.

Priced at $1,990.00 USD, the S&S Diesel Motorsport Ford 6.7L CP4 to DCR Pump Conversion presents a cost-effective solution that could potentially save owners between $10,000 to $15,000 in costly repairs. With this conversion kit, truck owners can confidently rely on their daily workhorse without fear of unexpected breakdowns. Moreover, the DCR Pump Conversion is emissions compliant (SEMA Cert #SC-SDM01-0034) and is compatible with 2011 to 2022 Ford F250-F750 diesel trucks, offering a comprehensive solution to a widespread industry challenge.

FEATURES & BENEFITS:

- Does not require any ECU calibration

- OE fit and function

- Two-piston DCR pump co-developed by S&S/PurePowe

- Biofuel and low-lubricity fuel compatible

- Patented Eccentric Drive pumping technology

- Pressure-lubricated cam and bushings

- Corrosion-resistant FCA

- 1,250 mm3/revolution displacement (CP4.2 + 25%)

- SEMA Certified Emissions Compliant (SC-SDM01-0034)

- Two-year, unlimited-mile warranty

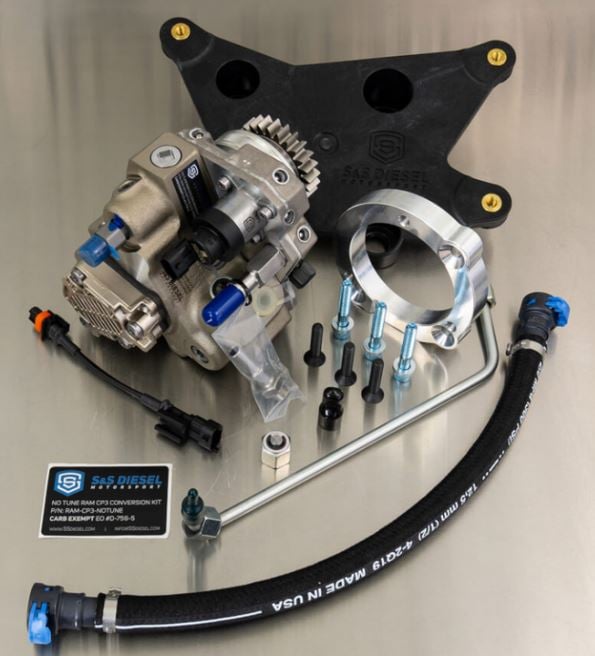

CP3 Conversion 2019-2020 Ram 6.7L Cummins

Second up on this list is the S&S Diesel CP3 Conversion for the 2019-2020 Cummins. This is a state-of-the-art solution designed to elevate the performance and reliability of Cummins diesel engines within this specific model range. This conversion kit represents a significant upgrade from the stock fuel system, offering enhanced durability and efficiency for diesel enthusiasts seeking improved engine performance. In the context of the CP3 Conversion Kit, it’s important to note Ram’s history with fuel injection systems.

From 2003-2018, Ram trucks relied on the CP3 injection system, renowned for its reliability. However, in 2019, they made a significant shift to the CP4.2 injection system, aiming for enhanced performance. Unfortunately, this change resulted in numerous failures and challenges in sourcing replacement CP4.2 units, promoting Ram to return to the CP3 system in the 2021 model years due to is proven reliability. For owners of the 2019-2020 models seeking a dependable solution, S&S has you covered.

By upgrading to the CP3 system, Cummins engine owners can experience improved fuel delivery, increased fuel flow rates, and consistent fuel pressure, resulting in enhanced engine performance and responsiveness. The S&S Diesel CP3 Conversion kit is meticulously engineered to ensure seamless integration with the existing components of 2019-2020 Cummins engines. Its plug-and-play design facilitates easy installation without the need for extensive modifications or recalibration of the engine control unit (ECU).

Crafted with high-quality materials and precision engineering, the CP3 Conversion kit offers durability, longevity, and peace of mind to Cummins engine owners. Whether for everyday driving or demanding applications, this conversion kit provides a reliable and efficient solution to upgrade the fuel system, unlocking the full potential of Cummins diesel engines.

FEATURES & BENEFITS:

- Significant upgrade over OE

- Robust, tried and true platform

- Improved fuel delivery

- Increased flow rates

- More consistent fuel pressure

- No custom tuning required

Reverse Rotation High Pressure CP3 Pumps

Lastly, rounding out our top three list from S&S Diesel Motorsport, is its Reverse Rotation High Pressure CP3 pumps. S&S Diesel Motorsport’s Reverse Rotation High Pressure Pumps represent a state-of-the-art solution designed to address specific challenges faced by diesel engine enthusiasts and professional racers. Unlike conventional high-pressure fuel pumps, which rotate in a standard clockwise direction, S&S’s Reverse Rotation High Pressure Pumps feature a unique design that rotates counterclockwise.

This innovative reverse rotation design offers several advantages. First and foremost, it provides improved fuel flow dynamics within the diesel engine’s fuel system. By rotating in the opposite direction, these pumps create a more efficient and uniform flow of fuel, optimizing combustion and enhancing engine performance. Furthermore, S&S’s Reverse Rotation High Pressure Pumps are engineered to mitigate wear and tear on critical engine components. The counterclockwise rotation helps to evenly distribute forces and reduce stress on the pump’s internal components, resulting in improved durability and longevity.

Additionally, these pumps are designed to be compatible with a wide range of diesel engines, making them a versatile choice for enthusiasts and racers looking to enhance the performance of their vehicles. Overall, S&S Diesel Motorsport’s Reverse Rotation High Pressure Pumps offer a unique combination of performance, durability, and compatibility, making them a valuable addition to any diesel engine enthusiast. Whether for everyday driving or high-performance racing applications, these pumps provide a reliable and efficient solution to optimize fuel delivery and maximize engine performance.

Offered in ranges from SuperSport to 14MM, there is a reverse rotation high pressure pump that will work with the other ingredients you have cooking up in your build. With support of up 2,000+ horsepower, this makes the choice for what kind of pump easy. Narrow down what your goals are for the truck, line it up with the features you need, and you’re off to the races. Quite possibly literally.

These high-speed, modified CP3s offer fueling capabilities up to 6,000 RPM (depending on which one), where an OEM pump falls short near that 3,000 RPM park. By upgrading, you’re preventing fuel starvation issues at higher RPM levels. If you’re taking performance seriously, these is the pumps for you.

FEATURES & BENEFITS:

- Improved fuel flow

- More efficient operation

- Optimizes combustion

- Enhances engine performance

- Reduces stress on internal components

- Improved durability and longevity