Written By: L.T. Tolman

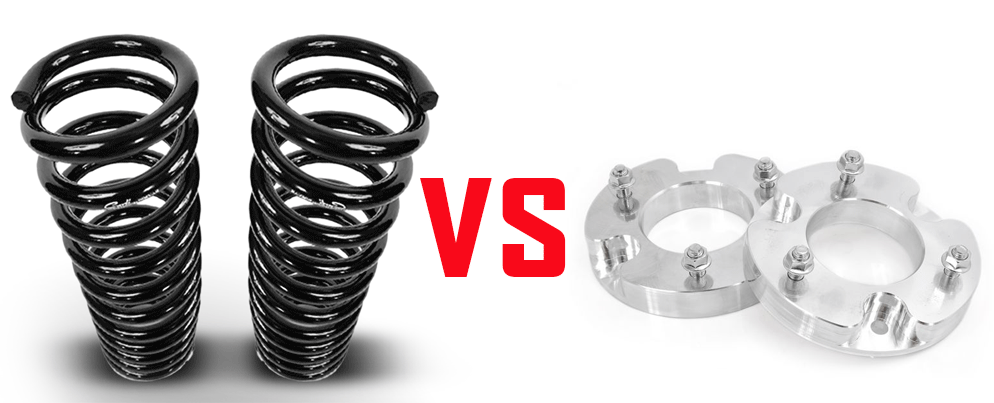

Since aftermarket suspension upgrades are so popular with diesel pickup owners, lately we’ve been taking an in depth look at several specific areas of suspension design. Today, we’ll focus on springs and spacers, and how they affect the height and quality of your heavy-duty truck.

Leveling Kits and Lift Blocks

If your main objective is to simply raise the truck to fit larger tires underneath, you can install a spacer between the coil spring and the chassis. This is known as a leveling kit, and it’s one of the first upgrades many will do to their suspension. It’s easy to gain between 2 to 3 extra inches of height for a modest investment, and installation is very easy, even for a DIY’er. There are several materials a spring spacer can be made from, including aluminum, steel, and even polyurethane. One important thing to keep in mind, is a leveling kit doesn’t improve wheel travel or articulation, and since you aren’t modifying the spring rate, your ride quality remains the same. Load carrying capacity is also unaffected with a spacer.

On a leaf sprung truck, the same concept can be employed to gain additional clearance in the rear, simply by adding a small lift block between the axle and the spring pack. Just like with a coil spacer, the stock ride quality and payload capacity won’t be affected, but there is one thing you have to be aware of, and that’s spring wrap. If you must use a lift block, I usually recommend no more than 4 inches on the rear axle, especially on a high torque diesel. The further an axle is away from the leaf spring, the more leverage it has to twist against the spring pack, which could lead to several issues like spring wrap or wheel hop, which may require the addition of traction bars to remedy.

Coil Spring Choices

While a leveled pickup sitting on larger tires looks good, many diesel owners get sick and tired of the harsh ride that comes from heavy-duty stock springs and look for ways to make the truck more comfortable. By replacing the stock coil spring, you can make your heavy hauler ride more like a Cadillac. There are a few types of springs you can purchase, and the main difference is their stiffness, or spring rate.

LINEAR RATE: A liner rate spring takes the same amount of incremental weight to compress each inch through its travel. For example, it might take 500 pounds to compress the first inch, 500 more pounds to compress the second inch, and so on. Carli offers linear rate springs for many popular applications, like the 4th gen Rams. Usually trucks that tow a lot, or heaver models will benefit from a liner spring. To smooth out the ride, the rate can be slightly less than stock, and by having the same rate throughout its travel, the truck can still carry extra weight and cargo without squatting down too far.

PROGRESSIVE RATE: The further you compress a progressive rate spring, the more incremental weight it requires. It might take 350 pounds to compress the first inch, 425 more pounds to compress the second inch, 500 more pounds to compress the third, and so on. There are several advantages to choosing a progressive rate: first you can have a much softer spring for the first part of the travel, giving a plush ride on pavement roads, which is where most truck owners spend much of their time. But as the suspension compresses further (like over a jump), the stiffer portion of the spring comes into play controlling the weight of a heavy truck and preventing the axle from bottoming out. Many long travel or pre-runner style race trucks use a progressive rate spring for the best performance off road.

Leaf Spring Options

The same progressive rate concept can be applied to leaf springs as well. Carli offers several different replacement leaf springs that will lift a truck and help it ride smoother than stock. The best ride can be attained with a progressive rate pack made from several thinner leaves. The lowest rate springs are on top of the pack, which will take away most of the harshness you’re familiar with. Since the leaves toward the bottom of the pack get progressively stiffer, the further the truck squats, the higher the spring rate goes up. You will sacrifice a little load-carrying capacity to get the softest ride in a 3/4 or 1-ton truck, but if you use your truck to work and can’t afford to lose any weight capacity, a variable rate spring can still help you, like with the Carli Heavy-Duty spring pack. They allow 15 inches of wheel travel and still have a softer rate spring up top for smoother driving, but the bottom leaves get much stiffer to support the extra weight of a trailer and heavy stuff in the bed. Additionally, the Carli Heavy-Duty spring pack eliminates the factory lift block, so axle-wrap and wheel hop is minimized.

Progressive rate coils are designed to be harder to compress (require more force) the more the coil is compressed.

Do you want fries with that?

Weather you choose a coil spacer or taller spring to lift your truck, there are a few add-ons you should consider installing at the same time. First and most important is a longer shock. Since the suspension will be sitting higher in its travel, a stock length shock can easily “top-out” or over extend, limit travel, and cause damage to the shock, so longer shocks will prevent that from happening, and restore full travel. When lifting a truck, it’s also a good policy to upgrade to a higher quality shock at the same time. When lifting a link style suspension, the front axle will move back toward the cab and slightly to left of center based on the geometry of the suspension. To correct this, adjustable length track bars and slightly longer control arms are also available to keep the axle where it belongs. These upgrades don’t really have any affect on the ride quality, but just help to correct the geometry of the axle in its new lifted position.

Since you have to live with your truck every day, why not make it more enjoyable to drive instead of just making it look cooler? There’s nothing worse than compressing a vertebrate when driving over a simple pothole, so why not spend a couple extra bucks, ditch the spacers and blocks, and get a proper set of springs? The best part is, it’s a modification your significant other will approve of as well.

I have a dodge 2500 cummins. I ordered new rims and tires. 33”x12.5 with a -44 offset. I don’t want to get new bars and what not to correct the geometry but how high of a lift will I need to go. I’d like the new shocks and springs idea. I don’t like the other parts I would have to install with a higher lift. Your help is greatly appreciated!

Hi there and thanks for the question. In order to fit that setup, you can get away with a 2-3″ leveling kit, but you will more than likely need to do a small amount of trimming to the rearward side of the front inner fender liners and possibly clip the corner off of the cab’s pinch weld to provide enough clearance when turning. If adequate clearance can still not be made with these modifications, then you would need to upgrade the control arms with something such as the Carli Extended Control Arms that push the axle forward and designed to work with a leveling kit. Lastly, if you do notice that one side rubs worse than the other, then you would also want to replace your track bar to an adjustable length version. Due to the triangulation of the steering and axle mounting points, as you lift the front end of the truck, it will shift the axle to the drivers side and the only way to correct this is with a longer track bar, or a drop bracket.