Written By: L.T. Tolman

A spring is the heart of the suspension system on every vehicle. They isolate the vehicle from bumps in the road, allow the axles to articulate, and hold up the entire weight of the vehicle and its cargo. If left un-checked, a spring’s stored energy can cause a vehicle to bounce uncontrollably up and down after going over a simple bump. Auto manufacturers found this out early on, so they needed to install some device to dampen the springs motion and smooth out the ride. That device is known as the shock absorber.

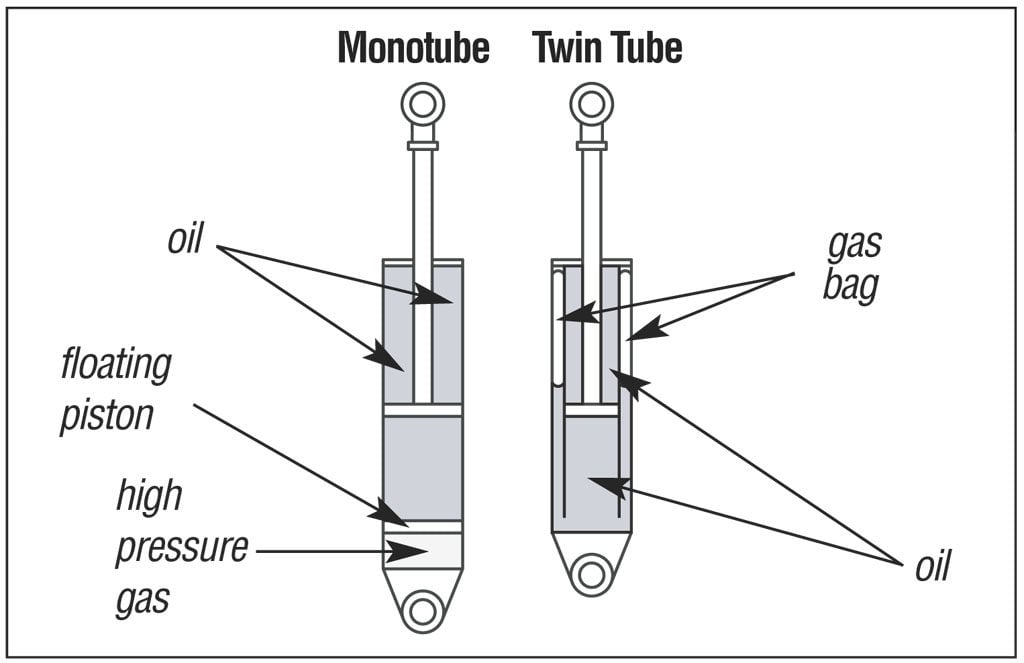

Today, just about every vehicle on the road uses a hydraulic shock. There are a few styles, but they all operate using the same principals. A shaft is connected to the vehicle’s suspension and runs into the body of the shock absorber which is filled with oil. A special valve is connected to the very end of the shaft, and as the suspension cycles up and down, the valve is pushed back and forth through the fluid. Tiny passages in the valve allow precise amounts of fluid to pass through, and this is what makes the shock work. The larger the passage, the less resistance to motion the shock will give, and the smaller the hole, the tighter. A shock absorber must be “tuned” to match the vehicle it’s attached to in order to work properly. The OE and aftermarket spend many hundreds of hours figuring this out, as there are a lot of variables to consider, from vehicle weight, spring rate, suspension travel, driving conditions, speed, and more.

We’ve been talking a lot lately about suspension systems lately, and in the diesel truck world 9 times out of 10 guys are lifting their trucks and want a smoother ride. As you can imagine, there are many different shock options out there, and it can be difficult to decide which to choose, especially if you fall on the high-performance side of the scale. Exclude generic “parts store” or stock replacement shocks from our discussion, today we’ll go over some of the options you can add to your pickup and what to expect in terms of performance.

It’s shocking how many options there are

Monotube/IFP: This is a great shock to choose for a lifted truck that spends most of its time on the street. A monotube like the Bilstein 5100 has a single internal oil valve that controls the motion of the vehicle. At the end, it has an internal piston which separates the oil from a chamber pressurized with nitrogen. This keeps the oil from aerating, which would hurt performance of the shock. A set of 5100’s will help control the suspension over mild terrain and help offset the extra weight of larger wheels and tires, plus give a smooth ride at an affordable price, usually less than a hundred bucks per corner.

Functionally, the Fox 2.0 shock is similar to the Bilstein 5100. It has a single non-adjustable fluid valve with the same kind of floating piston and nitrogen chamber, but the dimensions are a bit bigger. The Fox IFP shock has a larger 2.0” inside diameter, a larger 5/8” rod, and the body is made from aluminum rather than steel. This is an advantage because it won’t rust, but also helps dissipate heat from the shock oil. The harder you push your suspension, the more the shock oil heats up, and an aluminum body helps extract that heat, and keep the shock performing at its peak.

Performance/Adjustable: The next step up in performance comes with the addition of a remote reservoir, like on the Fox 2.0 Performance Series. Instead of putting the floating piston and nitrogen charge in the main body of the shock, it’s mounted externally which frees up some room in the body of the shock for more travel and fluid capacity, and more shock oil means it takes a lot more punishment before the oil gets too hot, and performance fades. In addition, an adjustment for compression dampening is now optional, allowing the end user to fine tune the ride of their truck to their liking.

Since more fluid capacity is the name of the game if you want to push your truck harder yet, the next size up is a 2.5” body with a 7/8” shaft. Here, we’re really getting into some serious shocks, and the rest of your suspension better be set up to match. Progressive rate springs, limit straps, and better sway bars will make a nice pairing with a 2.5, and now we have 2 adjustments; low and high-speed compression. This lets the user dial in a nice quality ride on the street and have great axle control during some really rough conditions.

Expect to open your wallet for a double adjustable remote reservoir shock; a pair runs in the ballpark of $1,000 to $1,400, but if you are a weekend warrior and push your truck harder and longer through the rough stuff, while still needing a comfortable and streetable option, it’s what you need. For 95% of drivers, a single adjustable 2.0 would be plenty, but there’s still more to come.

Multi-Adjustable & Bypass: At the highest level of (off-road) performance, a shock is going to have at least a 3.0” bore, as it needs to cope with more and more abuse. A shock of this caliber is so large, often frame modifications are needed to fit it into the truck, and reinforcements need to be made to the mount locations since the shocks can be very stiff when the going gets rough.

An external bypass is the crème de la crème. There are several tubes mounted outside the shock that allow oil to pass around (or bypass) the main center valve. Each tube has its own valve inside so you can fine tune different parts of the shocks travel. A bypass is almost like several shocks in one. In the middle of its travel, oil goes around the main valve for a soft ride over mild terrain, but near the ends of its stroke, all the oil must pass through the main valve, making the shock much stiffer, which prevents bottoming and topping out. Plus, you can adjust compression independent of rebound for the ultimate in control. Likely, a bypass shock will be found only on race only trucks; something that can run at triple-digit speeds through the desert for hours on end.

Make your choice

The short version is bigger isn’t always better. While you could throw a set of 3.0” Bypass shocks on your daily driver, you’ll honestly be wasting money, especially considering they can start around $1,500 bucks PER SHOCK. Yes, they may ride smooth on the street, but to get the most out of a bypass, you’ll need a well-engineered and high-dollar long-travel suspension system, and you’ll rarely push your suspension to the level where you’d actually need a set. At the opposite end of the spectrum, you don’t want to cheap out either, because a too small shock won’t be able to control the suspension, which is unsafe. It all comes down to picking a shock that meets your needs and ultimately your budget. For most diesel truck owners, a good shock somewhere between the Fox 2.0 IFP and 2.5 Piggyback will be the best choice for price, capability, and ride quality.