Written By: L.T. Tolman

As we continue our discussion of suspension design, the topic of link-style suspensions has come up a lot. Its been quite a few years since a solid axle truck came from the factory with leaf springs underneath the front, but have you ever wondered what makes a radius arm or 4-link work so well? And when you modify one of those systems, what challenges might you run into, and what can you do to fix any shortcomings? We’ll talk about all of that, but first we’ll go over the basics of how each system works.

A leaf spring holds up the truck and locates the axle under the truck. But since a coil spring only does one thing (hold up the truck) the other job of keeping the axle in place must be taken care of by a combination of metal links or arms.

Geometry 101

Radius Arm: Sometimes known as a 2-link, a radius arm is as simple as it gets. There are two arms that are fixed to the front axle on one end, and the other end mounts with a pivot on the frame somewhere near the transfer case. As the axle travels up and down on a radius arm truck, the pinion and caster angles are always changing, and the shorter the arm, the more those angles will change with wheel travel. One interesting byproduct of a radius arm is caused by the reaction force of the axle twisting when torque is applied; the front suspension can raise slightly under acceleration. Also, because of the nature of its design, a radius arm suspension has trouble articulating a lot, since the flex of the axle fights against the geometry or the arms, and they actually twist and deflect as the axle articulates.

4-link: In a four-link suspension, there are two pivot points on each side of the front axle, and two pivot points on each side of the frame, and the two bars on each side run somewhat parallel to each other, creating a linkage system that controls the axles movement. As the suspension travels up and down, the pinion and caster angle remain (mostly) unchanged, which can lead to better handling and road manners, and any twisting force from the axle is transferred directly into the frame rather. By design, a 4-link suspension will have much better articulation than a radius arm, and it’s also worth noting both styles of suspension system rely on a track bar to control the axles side to side movement.

The trouble with stock suspension, is its designed to operate in “stock” conditions. A stock length radius arm or link works perfectly for a stock height truck driving down a paved road. But when you want to get the most out of your truck and really push it harder off road, one of the things you need is an increase in wheel travel. Higher speed and larger bumps require more suspension movement to absorb all the shock. With a stock length radius arm, when the wheel travel increases, the amount of caster angle change goes way up, and since the axle moves in an arc, the front wheel moves further back as the axle droops with either design, which can give clearance issues between the cab and tires or wreak major havoc with a front driveshaft and U-joints.

The Fix

There is an easy way to cure some of the shortcomings of a link style suspension, and if you’ve ever looked underneath a pre-runner you can probably guess it has something to do with a longer arm. It all comes down to basic geometry; the further the pivot point is away from the axle, the less the pinion angle will change with travel, and front to back movement axle movement will go down as well. That’s all well and good in theory, but how does one go about making an arm longer? At the end of the day, most of us don’t have access to the engineering degree, skills, or tools required to build our own suspension parts.

If you aren’t looking to enter the Baja 500 with your daily driver, but just want to lift your truck a couple inches, extended length control arms are available which can push the axle forward, re-center the wheels underneath the fender, and prevent the tires from rubbing into the cab. But there are plenty of options for those wanting to push their truck to the next level as well.

The folks at Carli build top-notch suspension systems for many late model full-size trucks, and as you would expect, they’ve come up with a way to combine great handling and insane amounts of wheel travel into a system you can install in a weekend. Their 3-inch performance suspension system for the ’03 to ’09 Dodge Rams for example, boasts an entire foot of front wheel travel up front. Of course, the system comes with springs and shocks to make the ride smooth and absorb the bumps, but the heart of the system is the 4-ink which is 50% longer than stock. This additional length will create more wheel travel with less front to back axle movement, help the shocks to better control the axles motion, and gives better tire to cab clearance.

A radius arm suspension can also work great with a little help from Carli. In fact, their 6-inch radius arm suspension system for the 2003 to 2009 Dodge’s is touted as one of their most advanced suspension systems to date. It uses a longer radius arm and custom drop bracket for ideal geometry throughout its 12 inches of wheel travel, but it also has a unique hybrid design which allows for much more articulation than a standard radius arm design. The driver’s side arm looks normal, and its job is to keep the axle from twisting under acceleration. But instead of two matching arms, the passenger side radius arm features only one pivot point and an axle control shock which eliminates bind during axle flex and gives you the most articulation of any long arm conversion.

What to choose

Rarely do you find an upgrade or aftermarket part that has no downside but converting to a long arm style suspension is one. If you want a smoother ride, like to go fast over the rough stuff, need more wheel travel, want better handling, better suspension geometry, and stronger parts, it may be time to make the switch. Compromising on suspension should be the last thing you want to do, since you’ll notice the shortcomings each time you push your truck to the limit, or even during daily commuting. This is one of those instances when longer truly is better.

Extra Credit:

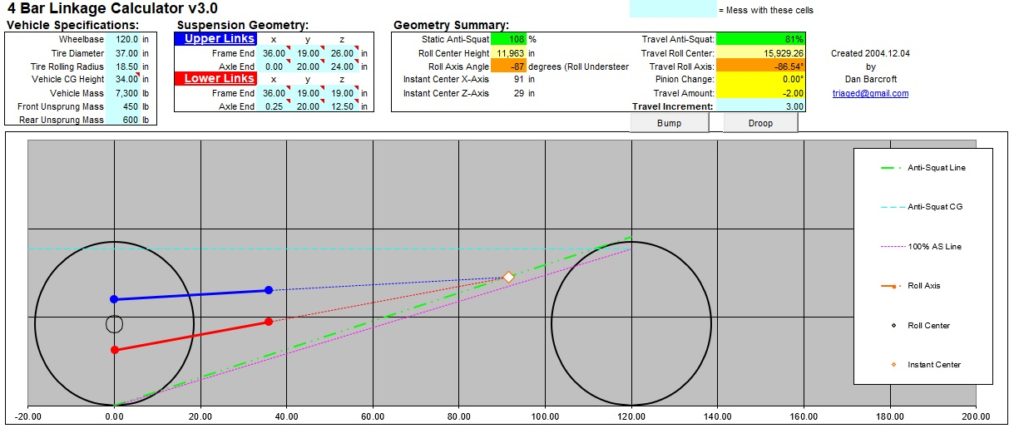

If you really want nerd out and learn more about the geometric properties of a suspension link, search for terms like Sagitta, Chord, and Arc-length, or download a suspension calculator and play around with the dimensions to see how various lengths and dimensions will affect the operation of the suspension.

Informative and spot on for what I’m planning to do.

My only question is:. Does Carli make a long arm for late model (2019+) Ram?

Again, thank you for a direct, but detailed, article.

Hi there and thanks for the question. To answer that, I’d say….sort of! The good news is that the new(ish) radius arms that Ram adopted in 2013/2014 (depending on whether its a 2500 or 3500), the trucks are already somewhat of a long arm, at least in comparison to the previous design that utilized upper and lower control arms. So, Carli makes a direct replacement arm, as well as a radius arm drop kit that can be used with their radius arms, or the factory ones. However, neither of these options are a traditional long arm, merely responsible for recentering the front axle after a mild lift is installed of around 3″ as that’s all Carli has at this point in time for these trucks, and all they feel is necessary as they’ve achieved substantially improved travel in comparison to the previous generation of trucks. Now, that’s not to say Carli won’t release something in the future, but at this time, there is not something available.