A quality driving experience can spell the difference between having a truck you want to use every day and a fast rig which stays parked in the shop because it’s a pain to deal with. The “driving experience” as a whole consists of several parts, but primarily has to do with things which make the truck accelerate, steer, and stop, but the transmission plays a big part as well. When they are delivered from the assembly line, just about every truck will provide a great driving experience: they have a smooth ride, are fairly responsive, and they have just enough power to haul around a trailer, however, fast is not an adjective I’d pick.

If you are not satisfied with how quick your truck is, all it takes is a quick scroll through your favorite diesel website, and you’ll find there are hundreds of performance parts available at the click of a mouse which can transform your rig from mild to wild. You need to keep in mind however, the further you stray from stock, the less and less comfortable your truck can become, especially if you pick the wrong combination of ingredients. Let’s look at turbocharging for example: you might be tempted to install the largest turbo you can find for its ability to crank out sky-high power numbers, but if you don’t have the matching fuel system to drive it, the proper gear ratio to keep the RPM’s in their sweet spot, and the proper torque converter to get the turbo spooled off the line, you’ll have a slower, smoky truck which feels way less responsive than before. It might make 750 horsepower for a split second, but the drivability could be so poor, you’ll be wondering why you bothered to upgrade in the first place.

Lost in Transmission

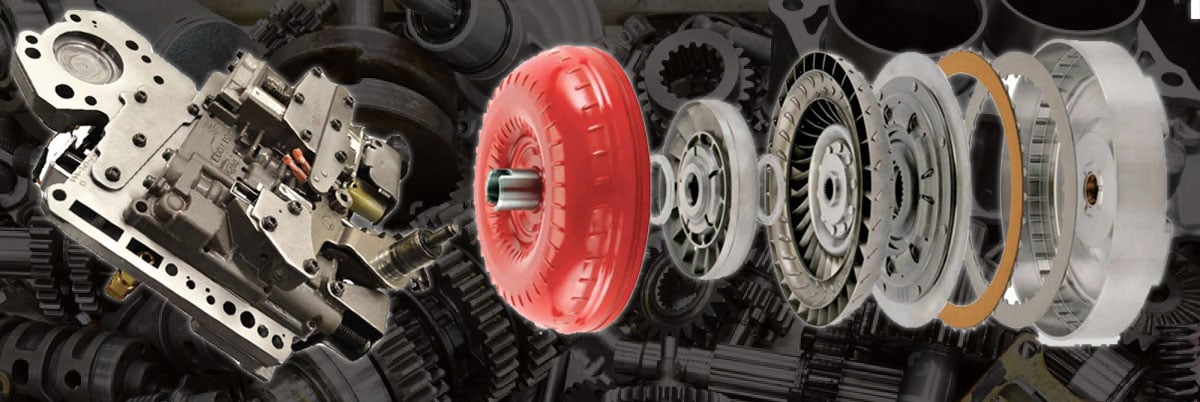

Transmissions can suffer from the same pitfalls and leave you with the same disappointment with your finished product if you don’t properly complete the parts recipe. Let’s say you’ve built a 750 horsepower Duramax, so of course the stock Allison just isn’t going to cut it. You make a call to the best transmission builder this side of the Mississippi and let him know you want the works: billet main shafts, extra clutches, a shift kit, raised line pressure, and a triple disc billet torque converter to top it off. When it’s done, you should have a transmission that can hold well over a thousand horsepower, but that doesn’t mean it’s going to be drivable, and a torque converter is the perfect example of how parts selection can make or break a build.

Every torque converter is rated with a “stall speed” which is the maximum engine RPM achieved if the transmission is in gear but the output shaft isn’t moving, and you can get a pretty close estimation of your trucks stall speed by holding your foot firmly on the brake while pressing on the accelerator as much as possible before the tires start to spin. The reading on the tachometer is roughly your stall speed, and a stock truck stalls somewhere around 1,800 RPM, but the aftermarket offers both higher and lower stall speed converters. For a diesel, turbocharger sizing is the biggest factor when determining what stall speed to choose, and ideally it will be close to the RPM at which the engine produces peak torque. If you have a stock sized turbocharger, you can take advantage of a “tighter” or lower stall converter which will couple the engine and transmission at an RPM where peak torque occurs, which will get the truck off the line with as little delay as possible, since the turbo is nearly spooled at idle. This will work great for work trucks which spend a lot of time with a trailer hitched to the back, or even a stock daily driver. On the other hand, if you have a single 72mm charger your engine will make peak torque at a much higher RPM, and a low stall speed would prevent the RPMs from increasing enough to get the turbo to spool, which means your first 60 feet are dismal. Of course, once the vehicle speed increases the larger turbo would eventually spool up, but a looser stall speed would make take-off many times better.

TCM Tuning

Modern electronic transmissions have every aspect of their operation controlled by a computer which is known as a Transmission Control Module, or TCM for short. In most cases, it’s a separate module from the engine computer and is mounted on the chassis or even inside the transmission, and its responsible for shift RPM, torque converter lockup speed, shift duration, and for some models, fluid pressure. The hydraulic circuits and electronic controls are each calibrated to deliver smooth and comfortable shifts at a stock power level, and the TCM is constantly learning and adapting, but with substantial increases in power levels, the TCM will be working against you. On top of that, if you alter the tire size or gear ratio in your differentials, your shift points will be all out of whack. Basically, the more you change in the drivetrain, the less your transmission is going to like it.

In order to correct the lackluster performance you can get with a modified truck, you need to make some tweaks, and a very popular method is to adjust the calibration of the TCM with tuning. First of all, you can correct for differences in tire diameter or gear ratio which will restore your factory shift points, but you can take things a bit further and raise the shift RPM to keep a big charger spooled up. Additionally, you can modify how soon the torque converter locks which helps acceleration, and also initiate a downshift with less throttle input to prevent the engine from lugging at a too low RPM.

I always recommend sourcing your TCM tune from the same vendor as your engine tuning because most ECU’s are torque based, which means they calculate the amount of torque the engine is producing and use that information to determine how quickly the clutches need to be applied. If you have an engine calibration from Tuner X and a transmission calibration from Tuner Y, then the expected torque values could be way off from one to the other, which will cause havoc inside the transmission. Also, once you get your TCM tune loaded in, resist the temptation to do a full throttle run right away. There is an important re-learn process which needs to happen any time you do a full flash of the TCM because any learned information will be erased during the flashing process. The TCM needs to re-learn the fluid volumes and apply times of each clutch pack, and this is an especially critical step on the Ford 6R140, because if the adaptives are not re-set, there is a very strong possibility you can cause damage to your transmission.

It’s also worth mentioning not every transmission controller has the ability to be re-flashed by aftermarket software, and that can affect how well the truck reacts to increased power. At the moment, the two biggest exceptions are the AS69RC which is found behind the 6.7 Cummins in some Ram 3500’s, and the GM 10L1000, the 10-speed automatic found in the 2020 L5P Duramax trucks. While you can add a lot of power to each of those platforms, the lack of TCM tuning will certainly leave something to be desired with the driving experience.

Lockup Boxes

A torque converter is great for multiplying torque and getting a heavy vehicle moving, but once the truck is in motion and the turbo is spooled up, locking the torque converter and eliminating slip will provide a more direct transfer of power to the rear tires and improve acceleration. If you remember, the timing of the Torque Converter Clutch (TCC) lockup is a parameter you can control with TCM tuning, but you can have trouble with the Allison transmission in particular. Because of the “smart” shift logic inside the controller, it doesn’t always behave how you want it to, and when every last second counts, you need the converter to lock up when you want it, and it needs to stay locked, even during a shift. Luckily, you can bypass the hit-or-miss TCM and ensure positive TCC lockup with the push of a button by using a Fleece AlliLocker. It’s a very simple add-on which simply taps into the TCC wiring circuit, and it gives you the option for the TCM to automatically control the converter clutch like it normally does for daily driving, or when you’re at the track, you can bypass the computer and lock the converter whenever you want with a switch inside the cab, and it will stay locked until you disengage it, which ensures the best possible MPH and ET.

Co-Pilot

While TCM tuning and a lockup box each have their place, some transmissions can really use some more help holding an increased amount of power, and the 2013+ Ram 68RFE is on the top of that list. From the factory, its line pressure is capped at 160psi, and the converter lockup strategy is iffy at best, and even if you command a higher line pressure with a TCM tune, there can be massive spikes and variations in line pressure. An ATS Co-Pilot takes control of the entire transmission, and makes improvements in several areas, making the 68RFE a much more reliable unit. It’s a comprehensive kit which comes with a new electronic controller, wiring harness, and in-cab control module, and it allows the driver to make adjustments to transmission line pressure and shift timing all based on throttle position and boost pressure. Under light throttle conditions, the Co-Pilot keeps things at a near stock level for a pleasant driving experience and minimal wear and tear on the clutches, but when you mash the throttle and the turbo comes alive, the line pressure can ramp up to 270 PSI for maximum clutch holding power and the torque converter locks up much sooner, allowing all of your engine’s power to make it to the ground.

Full Race Mode, Captain

For some transmissions, there comes a time to part ways with the TCM for good, and usually this happens while making the transition from a highway cruiser to dedicated race truck. For years, muscle car enthusiasts and drag racers have relied on a full manual valve body to shift gears, and believe me, it’s just as simple as it sounds. Basically, you throw the TCM into the garbage, and install a modified valve body into your transmission, bolt a gated shifter into the cab, and hop in the truck and go. Whenever the RPMs are just right, all you gotta do is reach down and bump the shifter forward one notch, and BAM! Next thing you know, your head is pushed back into the headrest, your engine gives every last ounce of power it can, and you’ll hear the screech of the tires as a full power upshift instantly happens. While a FMVB isn’t for everyone, they are appealing because you can eliminate any electronic glitches, and it’s the simplest way to ensure the transmission does exactly what you want every single time.

ManuMatic

Later model trucks come equipped with a “tap shift” feature which allows the driver to choose what gear the truck will run in when desired but will also operate like a normal automatic transmission. Today, it’s a standard feature on just about every diesel truck on the market, but in the early 2000’s, it was unheard of. On the Dodge 48RE for example you can pick your own gear, but to do so you’ll need to hit the overdrive on/off button which locks out 4th gear, but then you’ll have to manually move the shifter on the column to 1st, 2nd, or 3rd to select your gear. That is dangerous practice because it’s possible to over shift a gear, or even accidently bump it up into neutral or reverse if you’re not careful. Instead of messing around manually shifting on the column, a more civilized option is to install a BD Diesel TapShifter kit. It starts out by replacing the stock column shift lever with an OE style from a later model truck of the same brand, and near the end of the handle will be a small + and – button for picking your gear. The kit also comes with a wiring harness and control module which is necessary to allow the shifter to communicate with the TCM, and of course you also get a small digital display which lets you know what gear is currently selected.

BD Diesel offers TapShift kits to retrofit just about every truck, including the 5-speed Allison from 2001 to 2005, as well as the Ford 5R110 behind the 6.0 and 6.4 Powerstroke, and of course the Dodge 47/48RE, and the operation is very simple. You can drive just like you normally would by putting the shift selector into “D”, but if you want to override the TCM and decide on your own which gear is best, all you gotta do it reach for the little minus button on the shifter to bump it down into the gear of your choice. You can downshift a single gear to lock out OD while pulling a trailer, bump it down another gear for easy passing power, or use to take full control when taking off from a dead stop with a heavier trailer.

Finding Balance

Remember, all the power in the world doesn’t necessarily make the fastest truck, and a mismatch of parts on a highly modified truck can feel slower than a well-balanced truck with basic bolt on upgrades. In the same way you match your injectors and injection pump to each other, you need to pick your transmission upgrades to hold the right amount of power, but also to behave in the way you prefer. All it takes is some simple planning and a couple bucks in transmission parts, and you can create the ultimate driving experience from your diesel pickup.

Very well put together bunch of reliable information in regards to your heavy duty transmissions! Good information and product’s.