Modern diesel engines are great. They run quiet, pollute very little, produce tons of torque and are very efficient at moving the heavy vehicles they are installed into. The average 3/4 and 1-ton pickup nowadays weighs in at a staggering 8,000lbs or more, but it may surprise you that even with the bulk and aerodynamics of a full-grown elephant, they can still get close to 20 mpg when empty. Additionally, these pickups are still relatively nimble given their mass and can get out of their own way in a hurry thanks to 1,000 lb.ft. or torque.

There are a few reasons why a diesel engine can achieve such extraordinary feats. First, they have a compression ratio of around 16:1 which helps increase power production, second, they inject fuel into the combustion chamber at extremely high pressure which leads to the most efficient fuel burn as possible, third, they have sophisticated engine control modules which constantly monitor and adjust operating conditions, and finally, they use a turbocharger.

How a Turbo Works

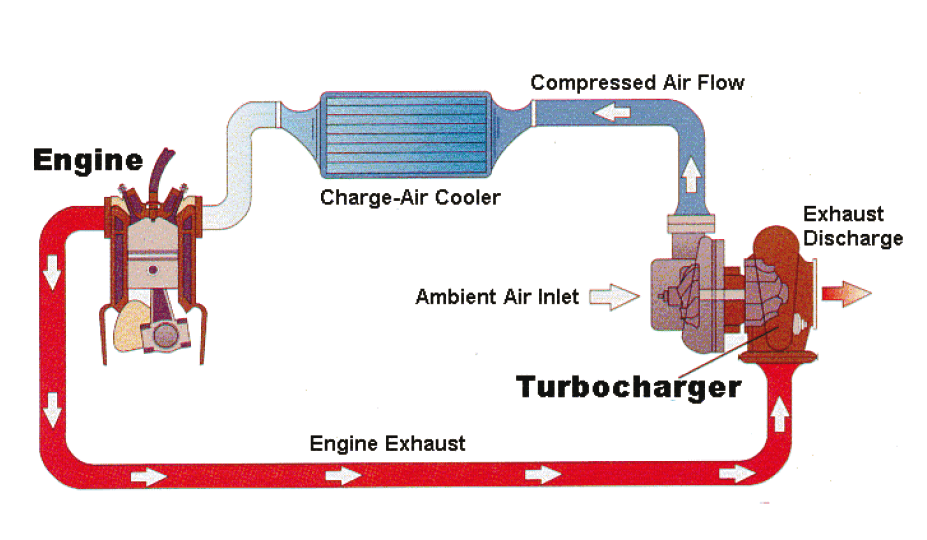

A naturally aspirated engine mixes air with fuel to create power, but the amount of air it can ingest (and ultimately how much power it can produce) is limited by its physical displacement and the amount of time the valve is open as the piston travels downward on the intake stroke. A turbocharged engine gets around this limit by force feeding air into the combustion chamber, and along with the extra air it can inject more fuel, which leads to more power and torque. Turbocharged gas engines like the Ecoboost V6 in an F-150 run a max of around 15 psi of boost, but in a diesel application the numbers are much higher. Stock trucks run near 30 psi, but on a modified diesel, the numbers can range anywhere between 40 to 100 psi (and sometimes even more).

After leaving the engine, exhaust gasses are routed into a turbine housing, where they spin a turbine wheel. A shaft is connected to the turbine, and on the opposite side is a compressor wheel which draws in fresh air and pumps it into the engine. If all the engine’s exhaust energy were allowed to spin the turbocharger, it would produce too much boost pressure and overspeed the turbo, so there are two different methods used to keep the turbo under control. The first is a simple mechanical device called a wastegate. It’s a valve that sits in the exhaust stream before the turbine housing, and as the desired boost pressure or turbo speed is reached, the valve opens via a diaphragm actuator and lets some exhaust bypass the turbine and go out the tail pipe. Diesel models with a wastegate include the LB7 Duramax, 5.9 Cummins (2007 and earlier), and the 7.3 Powerstroke.

As engine technology advanced in the mid 2000’s, designers found a better way to not only limit the turbo shaft speed, but also to reduce the spool up time of the turbocharger at low engine RPM using variable geometry turbochargers. It sounds complicated, but basically there are a series of vanes or nozzles inside the exhaust housing that direct gasses to different areas of the turbine wheel. This allows the turbo to respond faster and produce more horsepower at low engine speed, but also flow enough volume at high engine RPM without overspinning the turbo. VGT’s combine the benefits of both a small and large turbo and are central to the efficiency and power of modern common rail engines. Trucks that use a VGT include 2003 and newer Ford, 2004.5 and newer GM, and 2007.5 and newer Ram.

Can a Turbo Fail?

For the most part, factory turbochargers are very reliable and seldom fail, but when they do it can be hard to properly diagnose them and make the repair, and because of the cost of a new turbo, it’s not something you want to replace unless it’s truly necessary. If a turbo is on the way out, it can show symptoms like a reduction in power, decrease in fuel mileage, strange whirring/whistling noises, sometimes excess smoke from the exhaust, and most of the time a check engine light or message will show on the dashboard. If your truck has a boost gauge, it will likely show a lower pressure than usual, so pay attention to that as well. If you notice lower pressure than usual but no other symptoms, it’s wise to perform a boost leak test before going further, to make sure you aren’t losing air through a torn boot or damaged charge air cooler tube.

The center shaft of a turbocharger rides on either a bronze bushing or a ball bearing, but in either case, pressurized oil from the engine lubricates the shaft. Because of the speeds that the shaft spins, lubrication is critical for a long service life, but sometimes due to neglected maintenance, leaks, or even clogged feed lines, a turbo can be starved of oil. When this happens, the shaft won’t spin as fast as it normally will, and the amount of friction and heat inside will go up tremendously. This can cause accelerated wear on the main shaft, and the compressor or turbine wheel can even hit the sides of the housing, leading to catastrophic turbo failure. If you notice any symptoms and suspect this is happening, your best bet is to pull the intake tube off the turbo and look inside. Visual signs could include excessive oil film inside the compressor housing, scuff marks where the compressor rubs the housing, or damage to the blades on the compressor. One dead giveaway that you have a lubrication and bearing problem will be the play on the end of the shaft. A ball bearing turbo usually won’t have any play, and a journal bearing turbo will normally have minor side to side play, but if you can move the compressor wheel enough to touch the housing and you see evidence of this happening while the engine is running (scrape marks for example), the turbo is shot and should be replaced.

Usually, damage like this is only seen on extremely high mileage engines or very old trucks, but one much more common issue with a modern diesel turbocharger is on the VGT side of things. Because there are several moving parts inside an extremely hot and dirty area, sometimes the vanes in a VGT turbo can become stuck, the metal parts responsible for moving them can wear out, or the actuation mechanism can fail. 6.7 Cummins, 6.4 Powerstroke, and L5P Duramax turbos use an electric motor actuator, and 6.0 Powerstroke, LLY through LML Duramax, and 6.7 Powerstroke turbos use an electronic solenoid and engine oil pressure to control vane position. There are a few ways to test each, and on a Garrett VGT oil solenoid (used on both Duramax and Powerstroke applications), that’s done by measuring the resistance across the electrical coil on the solenoid. If it’s between 3.4 and 4.2 ohms when the engine oil temp is at 73°F, the solenoid is fine, and the problem is stuck vanes or a worn unison ring inside the turbo. More often than not, if you’re having problems with a VGT, it will be due to excessive buildup inside the exhaust housing. There is a lot of soot or carbon that can collect on the moving parts, and once is gets thick enough, the vanes will no longer be able to move when the actuator tries, leading to sluggish turbo response.

Suggested Parts and Upgrades

If you suspect a failed actuator or control solenoid, stock replacement parts are readily available and swapping them out is usually simple. Beyond that, most of the time when you have a problem with a turbocharger, the whole thing must be removed from the engine and be disassembled to inspect the internal parts. If the problem is just dirt buildup, you can get away with a thorough cleaning and be back on your way, but if there is internal mechanical damage, the fix is to replace the whole thing rather than rebuild it. Yes, rebuild kits are available with new bearings and seals, and of course you can buy new compressor and turbine wheels, but usually if you’re needing new rotating parts, the housings will be damaged as well, and at that point, you’re better off just getting an entirely new turbo. Luckily stock replacement turbochargers are available for all the common diesel trucks, and they will come complete and be ready to drop in with new solenoids, actuators, sensors, as well as new mechanical parts as well.

I never like to waste an opportunity for an upgrade, and the silver lining of a failed turbo is you can improve the response, power, and efficiency of your engine by installing an aftermarket turbocharger. Companies like BD-Power, ATS Diesel, Calibrated Power or Fleece Performance can take a stock turbocharger and apply some of their special sauce to improve the airflow through the exhaust vanes, install a slightly larger compressor and turbine wheel, and upgrade the bearings. This gives you a more reliable turbo which flows more air and spools up quicker than the stock version, which means more horsepower, better throttle response, and cooler EGT. The most popular drop in upgrade is in the 63-64mm range, and at that size, there are almost zero drawbacks. They will drop right in where your original came out, which means all your existing intake and exhaust piping will still work, and the turbo can support around 650 horsepower.

One more upgrade worth installing if the turbo has to come out would be the exhaust manifold(s), up pipes, and down pipe to increase the exhaust flow into and out of your new turbo. On a Duramax for example, PPE high flow manifolds and up pipes will lower EGT, decrease spool up time, and reduce exhaust drive pressure. They connect to your factory turbo and emissions components with zero modification which means they are 50-state legal as well. If you have a Cummins there are no up pipes to upgrade because the turbo connects directly to the exhaust manifold, but an ATS Pulse Flow exhaust manifold will offer the same benefits as PPE manifolds on a Duramax. In addition to lower EGT, quicker spool up, and more horsepower, the ATS manifold is constructed from two pieces with a slip fit connection in the middle. Because of the length of the Cummins engine, the one-piece stock manifolds are known to crack due to thermal expansion, but the slip fit design of the two-piece ATS manifold prevents this from happening. Once again, all your existing emission equipment will still attach, making the ATS Pulse Flow a 50-state legal upgrade.

Cummins Turbo Removal

Removing a turbo from any diesel engine can be accomplished at home with mostly basic hand tools, and we’ll start the overview with a Cummins. The first step is to disconnect the cables from both batteries, and then remove the simple stuff that’s in the way like the air intake tube and filter box. Next, disconnect the CAC tube going from the turbo to the intercooler, followed by disconnecting the exhaust down pipe. There will be an oil feed and return line that need to be disconnected, as well as coolant lines. If you have a 2007.5 or later Cummins, the VGT actuator harness will need to be disconnected. There will be four bolts that hold the turbo to the exhaust manifold, and once those are loosened up, the turbo can be maneuvered out of the way. It is possible to remove the turbo with the exhaust manifold still bolted to the engine, but the two turbo bolts closest to the block are very difficult to access. While it may seem like a bit more work, you can also leave the turbo bolted to the exhaust manifold, but instead remove the manifold from the engine with the turbo still attached, but just prepare for a little heavy lifting. With the manifold and turbo on the bench, it will be very easy to remove those inside two fasteners. If you are considering an exhaust manifold upgrade, this would be the time to do it. Once all the tear down is complete, inspect the oil feed and drain lines for any damage or restriction and replace if necessary. Then, throw on some new gaskets, and bolt the new turbo in place and thank your lucky stars you don’t own a V8 diesel.

Duramax Turbo Removal

On a Duramax, the turbo sits at the rear of the valley, but sadly most of the important connections are on the back of the turbo between the engine and firewall. Removing the intake tube is easy, as is the intercooler tube, but from there it’s an uphill battle. It’s pretty easy to get to the clamps that hold in the down pipe, but it does take an act of congress to slide it out of the truck, usually through the side using the fender opening. The up pipes attach to the turbo with three bolts each, and they will be extremely tight, and there’s not a lot of room for an impact gun. You can count on several busted knuckles, and if you’re lucky the bolts won’t break off. The oil drain line runs underneath the up pipe and attaches to the rear engine housing, and once everything has been disconnected, you can loosen the three turbo mounting bolts (they’re also extremely tight and difficult to get to) and then wrestle the turbo out of the valley of the engine.

Powerstroke Turbo Removal

Because Ford made so many design changes throughout the years, each generation of engine uses slightly different steps. The 6.0 Powerstroke turbo is easiest to remove, and since its mounted at a 45 degree angle to the engine and there are few parts in the way, it’s fairly easy to disconnect everything and remove the turbo. Plus, Ford used V band clamps instead of flange bolts which makes life simple.

If you have a 6.4 Powerstroke however, you’re in for a treat. Most people suggest lifting the cab from the frame to remove a 6.4 turbo, but it is not required. Because the 6.4 uses factory compound turbochargers, space is at a premium. Count on more banged up knuckles, and possibly broken tools trying to remove the up pipe to turbo bolts. Then, once you have all the hardware disconnected, you have to wrestle two turbos from the engine at once, and when you are putting things back together, it’s going to be very tricky to line up the oil drain tubes.

On a 6.7 Powerstroke turbo removal, it’s not quite as bad as the 6.4, but for some reason Ford decided to install their EGR and air intake system on top of the turbocharger, so much of the time on a 6.7 is spent just removing pipes and plumbing to gain access to the turbo, but once its exposed, the actual turbo replacement is pretty easy.

Once In a Lifetime Repair

Hopefully replacing a turbo isn’t something you have to do all that often, because on the “pain in the butt” scale, it ranks near the top. This is a job that you want to thoroughly research first, and make sure you don’t skimp out and reuse any small parts like gaskets, fasteners, or oil lines that possibly could bite you in the backside later on if they fail. Without question, tackling the job will cause you some grief, but saving the labor costs will allow you to make a few upgrades at the same time that can increase the reliability and functionality of your truck.

I have a 2007 Dmax LBZ, It recently started loosing cooling every couple of days I would have to add to the overflow tank. I was going to install a new water pump.

During the process I found an olive green color liquid in the intercooler and lower hose.

I have not been able to find any visual leaks, I believe it could be the turbo leaking. Any ideas or help would be great.

Thank you. FYI truck has 320,000 miles on it.

I have a F450 that has had changes to it ( manifold bolts) but the turbo blew white smoke then dark. Turbo has about 50 thousand miles on it at most. New parts everywhere. Can you help?

Thanks

When does a turbo start spinning, as soon as you turn key on or after engine starts?

I have a 2016 Ram 1500 with 3.0L diesel engine. There are about 230,000 miles on this vehicle. I believe the engine is manufactured in Italy.

Four days ago I started hearing a whistle noise on hard acceleration. I think engine power may be reduced but hard to tell.

I intended to remove the turbocharger and bring it in for repair. Then I found out the job involves removing the cab. It can be done from underneath without removing the cab by removing the transmission and transfer case. Either way, this is more than I can handle.

Can you handle a job like this?