There’s no question diesel trucks are built to be heavy duty, and if you consider the amount of weight they were designed to haul and how much power and torque they can produce, it makes sense why the parts in the drivetrain are so big. Four wheel drive is especially useful if you go off road or drive in slippery conditions, but there are a lot of extra parts needed to get the power from the back of the transmission to the front tires, and the list includes a transfer case, front driveshaft, front differential, and of course the axle shafts which transfer power while allowing the front wheels to turn back and forth. There are two styles of 4wd front suspension, IFS and Solid Axle. In the HD truck world, GM is the lone wolf in the IFS category, and it’s said their trucks have the smoothest ride of any diesel pickup. Ram and Ford on the other hand, have stuck with the tried and true solid axle under the front end of their diesels, and the main reason is strength and simplicity. Fewer moving parts generally mean a longer lasting front suspension, and the axles underneath are big enough to take whatever abuse you want to throw at ‘em, and the truth is most diesel owners can live with a slightly rougher ride quality, because after all, it’s a truck and not a Bentley.

Regardless of which design you prefer, there is usually some means of disconnecting the front wheels from the rest of the drivetrain, and the preferred method for the GM IFS and certain years of the Dodge Ram solid front end is a two-piece axle shaft with a disconnect collar on the passenger side. Ford does things a bit differently and uses a locking hub which uses vacuum to engage automatically, or it can be manually engaged by the driver twisting the end of the hub. For Dodges between 2003 and 2012, there was no means of disconnecting the front axle at all.

Shortcomings of The Stock Axle

When everything is working as intended, these 4wd systems are convenient and easy to use, but there are a few shortcomings to the modern solid axle design which can end up costing you big bucks in service and fuel. The solid front axles of today use a unit bearing to allow the hubs to spin, which is a sealed, non-serviceable part where both the inner and outer bearings are mounted very close together. This design saves space and makes for easy replacement but doesn’t give the bearings a lot of leverage strength against. This means when you install larger tires on your rig with a deep negative offset wheel, the forces applied against the unit bearing are increased exponentially and so they’ll wear out much quicker.

One other major problem with a solid front axle is how the decoupling is (or isn’t) handled. On the 3rd gen Dodge axle without a disconnect, when you are driving down the highway, even though the transfer case is shifted into 2wd, both front axle shafts, the carrier, ring and pinion gears, and even the front driveshaft are still being turned by the tires. Basically, you are using energy to spin a bunch of heavy parts around hundreds of times per minute for no reason, or in other words, you’re wasting fuel. Having a two-piece passenger side axle like the 94-02 Dodge means some of that senseless spinning is eliminated, however you now have an extra point of failure which could cause problems if you are sending a lot of power through the front axle, or in some cases, the vacuum actuator can fail, leaving you stranded and stuck with only 2wd.

Ford handles things a bit differently with their axle, and in the center of each front wheel there is what appears to be a manual locking hub just like the old school trucks used to have, but they still use the weaker unit bearing design, and there is also a vacuum operated locking mechanism hidden just behind the brake rotor which lets the drivers engage 4×4 without having to get out of the truck and get their boots dirty. While the system is semi-reliable, there is always the chance of failure, and the biggest flaw is still the unit bearing.

Free Spinning is Winning

As luck would have it, there is a way to eliminate all the problems associated with the newer style solid front axles and increase strength at the same time. The first step is to convert to a manual locking hub which uses a traditional tapered roller bearing with a Free Spin Heavy Duty Hub Conversion from Dynatrac. They make kits for both Ram and Ford, and even though the axles operate differently, the Dynatrac kit does the same thing for both: get rid of all the weak unit bearing and install some premium American steel in its place.

The Free Spin Kit starts with a chromoly spindle which bolts directly to the knuckle where the factory unit bearing once lived, but now allows for a set of traditional tapered roller bearings to be installed with a wider spacing for increased strength. While that by itself is a huge advantage, by using a replaceable bearing, you can also take apart the hubs and re-pack the bearings with grease as the miles rack up, or if the bearings ever do wear out, it’s inexpensive to swap ‘em out for a new set which you can find in almost every parts store in the country. The new spindle accepts a hub with the same bolt pattern your truck currently has, and the biggest difference is the manual locking hub which disconnects the rotating wheel from the rest of the axle, so there is no wasted energy from turning the front differential components, which in turn gives the added benefit of an increase in fuel mileage. The kit includes a stout 1.5” 35-spline outer axle shaft which is engaged by a Warn premium locking hub, so whenever you twist em into the locked position, there’s no question you will have power flowing to the front wheels to get you out of a jam.

For most owners who operate their truck on the farm, in the snow, or through the desert, the standard Warn locking hubs offered in the kit will work perfectly, but if you have a souped up powerplant under the hood and suffer from heavy-right-foot-itis, the prescribed cure is the Dynatrac Dynaloc hubs which are available as part of the Free Spin Kit, or as a standalone upgrade to an older axle. They are an all-new design and constructed from heat treated chromoly and are 3 times stronger than a traditional locking hub. They also have a lower profile which means they are less likely to get damaged by rocks or trail obstacles, and they easily engage or disengage with just an 1/8 turn of the knob.

There is one final benefit to the Free Spin Hub Kit worth mentioning, and that has to do with hauling a trailer. Every now and again you’ll find yourself in a situation where you need a little more leverage to move a heavy load at a slower speed but might be on a solid surface and can’t use 4wd low range. By converting to an old-school manual locking hub, you now will have the option to simply shift the transfer case into 4-lo but not engage the hubs which means you actually are in 2wd low range. Now it’s so much easier to move that heavy trailer around the lot and you won’t be binding up the front end on concrete or pavement trying to turn while in 4wd low range.

While You’re in There Doc…

Once you’ve made the decision to convert to a free spin hub, you need to consider the amount of work it will take to install the kit, as a major portion of the front axle will have to be disassembled to gain access to all the parts required to make the swap. While it’s not really a huge deal for anyone who turns wrenches more than once a year, it is a good opportunity to upgrade a few other parts in the axle while you are doing the job, and the very first thing I would get rid of is the two-piece passenger side axle, if equipped. Since the axle disconnect system will already be redundant with a free spin hub kit, you could just lock it out by modifying the vacuum actuator or shift fork, but that still leaves a potential for failure since you’re connecting two splined shafts with a simple collar. Sketchy.

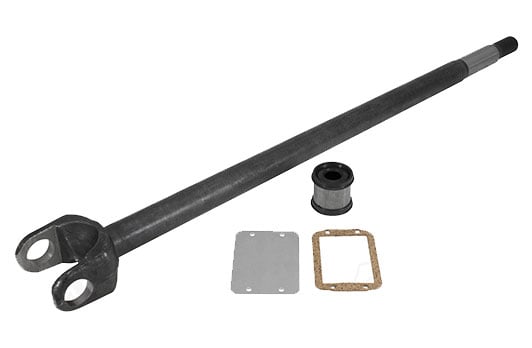

A better alternative is to replace it entirely with a much stronger Yukon Disconnect Axle Delete Kit. Because you are removing the stock 2-piece axle to install the free spin kit, there is practically zero extra labor to just swap it with a one-piece shaft which is a major step in the right direction, but in addition, the Yukon shafts are made from 4340 Chromoly steel which is much stronger than the alloy of the stock shafts. If you wanted to take things a couple notches further for your race truck or sled puller, you can also choose the 35-spline version of the axle shaft, but to do so, you need to swap out the spider gears or the whole carrier, as the stock 30-spline carrier won’t work. Even the 3rd gens with a one-piece stock axle can benefit from a swap, since Yukon also makes a 4340 Chromoly shaft for you as well, and they are 50% stronger than stock.

If you decide to keep the stock shafts in place, it would be crazy not to at least replace the U-joints with some new non-greaseable Spicer joints because you are already going to be disconnecting the u-joint from the outer axle shaft. You might think a non-greaseable joint is a step backward, but it’s actually much stronger than a greaseable joint, since the hole for the grease is actually a huge weak point. Besides, they are permanently lubed which means one less maintenance item to worry about. If your truck has a lot of miles on the odometer, the carrier and pinion bearings inside the front axle may have worn out, or at the very least, there’s a good chance your stock axle seals are leaking gear oil, so now is also the perfect opportunity to clean things up with a new set of inner axle seals, or if you want to make sure the entire front diff is as good as new, the easiest way to get all the small parts you need is with a master install kit from Yukon.

Pain in the Ball Joint

If there is one job which any tech shies away from, it’s got to be replacing the ball joints on a solid front axle. While it isn’t necessary to disconnect the ball joints from the knuckle to install the free spin kit, you are 90% of the way there, and if yours are just worn from wider tires, it’s a great time to swap em out for some fresh parts to restore the tight steering feel your truck had when new. If you are in fact running oversized tires, then chances are you’ve worn through your fair share of stock parts, so it might be time for an upgrade. Dynatrac also makes the Prosteer HD which is the last ball joint you will ever have to buy for your truck, period. They are 3-4 times more durable than the OEM design, they’re made from high strength billet steel, and are fully rebuildable. Finally, as you are wrapping up the job, it pays to give a quick inspection and see if the brakes are worn out since it would be so easy to throw on an upgraded pad and rotor combo to help slow your truck down with the oversized wheels and tires.

Where to Stop

According to Wikipedia, a snowball effect is a process which starts from an initial state of small significance but builds upon itself becoming larger and larger. When building a truck, you can see how the parts list can easily grow, but it’s all in the name of durability and better function. As you ask more from your truck than it was designed to give, you will need to make several modifications to each system to help it cope, and the front axle is not exempt from this rule.

The Free Spin Kit makes a huge difference simply by eliminating the unit bearings, but also increases efficiency at the same time by reducing drag, but by changing out a few simple parts during the installation, you can easily create one bulletproof front end which you’ll never have to worry again. Sure, you’ll have to hop out of the truck and engage the hubs when the going gets tough, but that’s a small price to pay for peace of mind.

This post was super helpful. I drive a 2008 dodge 2500 and would have never known I was at this risk. Will definitely be looking into the free spin kit for my yruck.

I have a 91 dodge Cummins one ton dually 4wd. The front springs look weak. Any ideas?

You bet, you’ve got a few different options. The first thing you could do is have your front leaf springs rebuilt, as you’re probably right, the metal is aged and fatigued, thus probably sagging a fair amount. In some cases, the entire leaf spring does not need to be replaced, but again, can be rebuilt, only replacing some of the lower leafs, for instance. Another option would be to merely add air assistance to the front springs through a front suspension air bag kit, similar to what most would use on the rear of the vehicle, such as the below kit from PacBrake. And finally, if you’re also looking to lift the truck, you could go with a complete lift kit that would include new, longer/taller front leaf springs, and for this, we carry systems from BDS Suspension and a few others. Hope this information helps, and if you have any other questions, feel free to message back.

Front Air Bags: https://www.dieselpowerproducts.com/p-19452-pacbrake-hp10086-amp-fabricators-large-front-air-spring-kit.aspx

I installed the Dynatrac free-spin kit plus upgraded hubs on my ’06 Dodge 3500 in December 2019.

My mileage has improved, steering feels wonderful and I have piece of mind. Your article was fun to read as I nodded at each recommended option, most of which I wisely did. Thanks for the write up.