When it comes to building a high-performance truck, Ford just doesn’t get the same amount of love that the other brands do. The 7.3 Powerstroke was super reliable but slow as molasses, the 6.0 had its issues for sure, and Ford was the last to adopt common rail technology, a full 5 years after Dodge. They do make a very solid truck, and they get my vote for the nicest interiors available, but for some reason, you see way fewer high-performance or race builds using the Ford platform. Today we’ll look at some of the challenges, but more importantly focus on how you can hop up your blue oval Superduty to make another 300 horsepower over stock. For now, we’re skipping over the HEUI trucks like the 7.3 and 6.0 and focusing on the common rail engines, which means 2008 model year and onwards. And it all started with the 6.4.

6.4 Powerstroke: The Hot Rod Diesel

Even though Ford was the last to switch to common rail fuel injection, they wanted to hit it out of the park, and they did just that. The 6.4 Powerstroke (or MaxxForce 7 as it’s known in industrial applications) was developed by Navistar International, and had a few features which set it apart from its competitors in the diesel pickup market. It was a 6.4 liter four-valve diesel V8 and used a Siemens VDO K16 injection pump which is said to outflow the Bosch CP3 used by Dodge and GM by 20%, which gives the 6.4 a distinct horsepower advantage. In addition to the high flow pump, the 6.4 also featured the first and only stock compound turbos on a pickup truck measuring in at 52mm and 65mm respectively, which meant excellent low RPM throttle response and great high RPM power all at the same time. Combine all this with the large stock injectors, and you have a recipe for a hot rod. While the engine left the assembly line with a rating of 350hp and 650 pounds of torque, no other diesel truck has as much power left on the table as the 6.4 did. In fact, it was common to see trucks putting down an additional 300hp over stock with nothing more than an intake, exhaust, and a race programmer. However, just because you can do something once, doesn’t make it a good idea to do it repeatedly, and many 6.4’s paid the ultimate price because of over enthusiastic tuning…

Keeping a 6.4 Cool

When adding power to any diesel engine, you need to remember this basic formula for EGT, the most important parameter: fuel makes power but adds heat, and air cools things off. In order to make that 300+ additional horsepower, race programmers would take advantage of the massive capacity of the stock fuel system on the 6.4 but would also try to add more air with the stock turbos, but that is where the restriction lies. The stock compounds create a backlog on the turbine side, which causes a buildup of heat and drive pressure in the exhaust system. If left unchecked, the combination of aggressive tuning and stock turbos can (and has) cracked many pistons. When properly modified to keep heat under control, many stock-bottom-end 6.4’s have made nearly 900hp and lived to tell the tale, so it’s not a strength issue, but rather a heat issue. For the 6.4 we’ll focus not so much on adding power, but rather how to manage the heat that power creates, and once the heat is under control, then we can talk about adding a bit more fuel.

Too Much Exhaust and Not Enough Air

If your power goals are near the 550whp mark, you already have the hardware to make that a reality, but you need to take a few steps to increase the longevity of your engine, and installing a wastegate is a great way to do just that. Since a tuned 6.4 makes much more exhaust than its turbine housings can flow, bypassing the excess volume with an H&S Wastegate Kit will reduce exhaust backpressure by half, lower EGT, and as a side effect you’ll see an increase of 10 and 30 horsepower. The next items on the docket are the exhaust manifolds and up pipes which lead to the turbos. The stock thin-wall up-pipes are prone to cracking where they take a 90˚ bend at the exit of the manifold, and the manifolds themselves are restrictive. Like any good exhaust upgrade, BD Diesel’s Up Pipe Kit will improve spool-up time, reduce exhaust gas temp and back pressure, and the heavy wall construction of the up pipes and cast manifolds will eliminate the possibility of cracking and blow outs.

Once you want to push the power numbers past the 550 mark, the turbochargers will need to be addressed. The stock compounds become too restrictive and will quickly run out of their efficiency zone, so to increase airflow into the engine there are two schools of thought: the first and simplest is to swap the stock compounds for a single fixed geometry S300 style turbo using an H&S Motorsports SX-E Single turbo kit. The 73mm turbine wheel and exhaust housing will drastically reduce EGT and back pressure, and depending on which size compressor wheel you chose, it will support between 575 and 750 horsepower, all while keeping your engine much cooler and happier than with the stock turbochargers. The second school of thought is to keep the compounds but make ‘em bigger. Swapping your stock turbos for an Industrial Injection Phatshaft 71/58 kit will deliver the best of all worlds. Massive low RPM torque and quick response combined with lots of high RPM power, and of course you will get cool EGTs and quick spool up, all while supporting up to 750 horsepower.

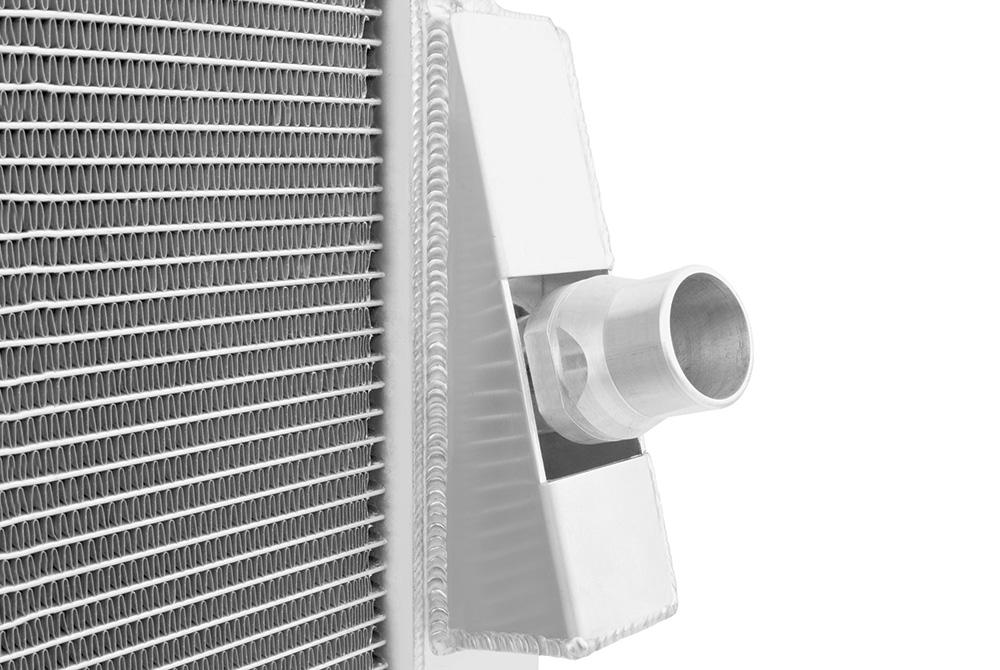

When adding horsepower to a diesel, reliability and cooler temperatures are of utmost importance. The stock intercooler does OK with lower power levels, but a larger Mishimoto Intercooler is better suited to an increased power level, since it will remove much more heat from the compressed air, and it creates less pressure loss through the intercooler, and much more air density enters the engine. By also swapping the stock crimped boost tubes for the included larger mandrel bent pieces, all parts of the airflow equation are now solved. And while you are working on the cooling stack, it would be smart money ahead to also swap out the leak-prone stock radiator with a welded Mishimoto unit, since the plastic tanks on the stock radiator will most certainly fail sooner or later. With the airflow upgrades taken care of, the truck will be responsive and have cooler EGTs, and most important, increased reliability and reduced chances of cracking a piston. So now, it’s time to add some more power with extra fuel.

Fuel the Fire

With any common rail diesel, the fuel system needs to be proportionally upgraded in three separate areas: the injection pump to supply more high-pressure fuel volume, the injectors to allow more fuel flow into the cylinder, and the lift pump to deliver more low-pressure fuel up to the injection pump. Even though a 6.4 has lots of fuel capacity in its stock form, once you go beyond 550-600rwhp the injection pulsewidth gets a bit too long which puts undue stress and heat on the pistons, so a larger nozzle is necessary to deliver more fuel in a shorter amount of time. If your stock injectors are in good health and have lower miles, you can save a bit of money over a full set of injectors by installing some high-flow Dynomite Diesel 30% over stock nozzles. They will support roughly 675 horsepower at the wheels which is perfectly matched to the turbochargers mentioned earlier, and the best part is since they can now run at a shorter pulsewidth, your EGT’s will go down which means a safer and longer lasting performance based engine. On the low-pressure side of the fuel system, the stock lift pump will be tapping out by now, and it should be swapped out for a higher flowing version. The FASS Titanium Signature Series 165 is a great solution. It will support up to 900 horsepower, but also cleans the fuel better than the stock pump and filter, removes any trapped air which helps your injectors and injection pump last longer, and of course the FASS will remove any water which is often found in diesel fuel.

There are a few odds and ends which should be taken care of to wrap up a 6.4 build. This version of the Powerstroke uses a massive 16mm head bolt from the factory, but it’s a torque to yield design and made from a barely adequate material. ARP head studs are made from an alloy which is rated at 200,000psi of tensile strength and will do a much better job of keeping the heads firmly attached to the block, sealing the combustion pressure inside the engine where it belongs. If you are far enough inside the engine to install head studs, it’s also the perfect time to throw in some Hamilton Valvesprings which will prevent the valves from being blown open from higher drive or boost pressure, but will also prevent valve float at higher RPM.

There have been a few people who push the 6.4 well beyond the 750hp mark, but its not very common. Since it’s a three year only engine, it is a bit more difficult to find off-the-shelf solutions, however it is a very popular engine amongst the sled pulling crowd, since the 6.4 is a very stout platform which holds up well to high RPM and insane amounts of boost. If you have goals of 1,000hp, just be prepared for some custom fab work and a bit of creativity.

6.7 Scorpion Overview

In 2011, Ford introduced its first diesel engine which was manufactured entirely in-house. It was a 6.7-liter V8 powered by the Bosch CP4.2 injection pump, and it earned the nickname “Scorpion” due to the unique arrangement of the exhaust ports in the valley of the engine and the curve of the up pipes entering the turbo. The powerplant was originally rated at 400hp and 800lb.ft. of torque and used a unique Single Sequential Turbo (SST) which was basically a single turbo with a dual sided compressor wheel. Slight changes have been made throughout its production run including a few revisions to the turbocharger, but the basic engine design remains the same today as it was back in 2011. Right out of the box, the 6.7 delivered much better fuel economy than the 6.4 and more stock horsepower as well, but the 6.7 did not have as much high-performance potential as the earlier 6.4, which just means builders have to work a bit harder to extract more power.

6.7 Recipe

Of course, the 6.7 responds to the basic intake, exhaust, and programmer which most drivers start with, but there is one thing to watch out for if you own a 2011-14 model 6.7 with a hot tune, and that’s the turbocharger. It’s very easy to get the Garrett GT32 SST spinning too fast, and if you do, it’s like a ticking time bomb. There have been many well documented cases of a stock turbocharger failing, and rather than replacing it with a similar design which will fail again, its common practice to retrofit the much more reliable 2015-16 style Garrett GT37 VGT, but it’s not a simple bolt in affair. There are a few parts which need to be swapped out to make the conversion, and No-Limit Fabrication makes it easy with their Turbo Retrofit Kit. While you could bolt on a stock ’15-16 turbo in place, it doesn’t make much sense from a performance standpoint, but instead an option like the Fleece Cheetah 63mm FMW will drop right in with the conversion kit, and will support up to 650 horsepower while retaining factory like drivability and quick spooling, all while keeping EGT’s under control.

If you want to take your 6.7 Powerstroke much higher than the 650-horsepower mark, you will have to get a little creative on the turbocharger side of things, mainly because of how many parts need to be packaged in such a tight space. If you use your Superduty for towing and quick throttle response is your goal, then a compound turbocharger setup is what you’re after, but your options are a bit more limited than if you owned a Duramax or Cummins. Luckily, Industrial Injection does offer an Add-a-turbo kit for the ’11 to ‘14 6.7’s. It uses a Borg Warner S475 as the atmospheric charger which makes for a very well-rounded pickup which can tow heavy loads while maintaining low exhaust temps, but the truck will also work well at the strip.

If you want to go a little more on the racy side and don’t need the low RPM EGT control a compound will give, a large single turbo is the cat’s meow. The feeling it gives when the boost comes on hard at the mid RPM range it hard to replace, and the SX-E family of turbos will provide that hit you’re looking for but are also durable and will last for many miles to come. BD-Power has come up with a way to fit an S366 SX-E charger underneath the hood and you get everything you need with their install kit. It features high performance T4 exhaust manifold, billet aluminum pedestal block, and all of the necessary components you’ll need for a complete installation. This kit will easily support over 600 rear wheel horsepower and substantially broaden the power curve.

To get enough fuel to make a big single work properly, you’ll need to install some larger injectors and a FASS lift pump just like you would with the 6.4, but the trick on a 6.7 is getting enough high-pressure fuel into the rails in a reliable manner. The stock Bosch CP4 is failure prone as we know and keeping the rest of the fuel system safe from the fallout when it fails is possible, but it requires accessing the pump to install a CP4 Disaster Prevention Kit. This is a reliability measure, and while it won’t keep the CP4 from melting down or add capacity, it will keep the shrapnel out of the injectors when a failure occurs. The extra fuel capacity will come from a second injection pump, and a BD Venom Dual Fuel Kit allows the older but more reliable Bosch CP3 to provide the extra fuel needed for any level of power you want. It comes with a stock displacement pump which combined with the stock pump will support around 1,000hp, but you can also swap to a larger 10 or 12mm stroker pump for even more power.

One of the unique features of the 6.7 Powerstroke is the water to air intercooler (or heat exchanger) which is used in lieu of a traditional air to air which most diesels use. By design, it does a much more efficient job of removing heat from the compressed air which means it can be a lot more compact. Ford mounted the intercooler in the driver’s side inner fender well, and much like a traditional front-mount air to air intercooler, it will run out of efficiency at an elevated power level, plus it is possible for the stacked plate design to crack and leak boost pressure, so Mishimoto has developed a bar and plate style replacement intercooler which is TIG welded together with cast aluminum end tanks, and will withstand any amount of boost you can throw at it, but it will also outflow the stock cooler by 22%, and that increase in airflow will lead to an increase in torque by 40 lb.ft all by itself.

Cab-off Consideration:

When you are building a Cummins or a Duramax, most of the external performance parts we talk about are somewhat accessible in the engine bay, and you can usually install the parts in an order that makes sense from a power and budget standpoint, spread out over a few stages. Usually, I like so start with the airflow parts like manifolds/up-pipes and a turbo upgrade, and then move onto the fuel system whenever your budget allows. However, with a Powerstroke, you need to be a little more thoughtful and patient when planning things out. You might not know this, but in order to access some of the parts deeper in the engine bay, you really need to remove the cab from the frame. That may sound drastic, and granted, it is a job most DIY’ers will shy away from. In all honesty, a shop which specializes in Fords can have the cab off the frame in a couple hours giving unrestricted access to the engine and all its components, but it will cost you extra in labor if you are farming out the job. As such, it’s important to plan your upgrades and budget to do as many cab-off items at the same time so you don’t have to come back six months later and remove the cab again for more parts.

To Build or Not to Build:

The Powerstroke doesn’t get as much love as the Cummins or Duramax when it comes to high power builds, but it is possible to make a fast Ford. The 6.4 is by far the easiest truck to get extra power from, but it also needs the most help controlling temperature of combustion. The 6.7 is a great engine which makes a lot of power from the factory, and it too can be made faster, but its biggest challenge is under-hood space for aftermarket turbos, but the best part about hopping up a Ford is they have some of the strongest (stock) transmissions out there.

When modifying any diesel engine, it can be a bit of a challenge to choose what parts to add in what order, and my general advice is to take care of the air before you dump extra fuel into the engine. If you need help deciding which direction to take on your build, what turbo to choose, or which size injector will meet your needs, be sure to give the guys at Diesel Power Products a call. They are all experts and enthusiasts, and they’ve likely installed the very parts you are asking about, plus they can help you pick out parts which will make your truck faster and more reliable, all at the same time.

Love your articles and very helpful. Looking to use your tips in the future.