Which wheel do you want? Whether you want a set of big inch polished forged wheels for your show truck or a set of 17” Beadlocks for the pre-runner, there’s no wrong choice, because it’s all about your own style and what fits the theme of your truck. There are more individual types of wheel than any other automotive part, so the first hurdle is sorting through the thousands of styles to find the one which is right for your build, but the second challenge is actually selecting a size which will fit your application. Once you start digging, it quickly becomes clear there is a lot of very important information you will need to know before you whip out the master card and get some new wheels on the way.

The Basics of Sizing Wheels

Every wheel on the planet can be classified with a few key dimensions, and every car guy should be familiar with the basics. For our first example, we’ll use a popular wheel from Icon, called the Rebound which is classified with the following information:

- 17 x 8.5

- 8 x 6.5 bolt pattern

- 5.25” backspacing

- +13mm offset

Simply by looking at those few pieces of information, you can tell a lot about that wheel, from what kind of truck it will fit, to how far it will stick out, and what size tire you can run. Item one is what describes the size of the wheel, and the diameter is always the first number listed, followed by the width, and these are always measured in inches. The second piece of information describes the wheel bolt pattern, which is how many lug studs there are and how far apart they are spaced, which lets you know what type of vehicle the rim will fit on. The first number is the quantity of lugs, and the second is the spacing between the lugs. Wheel bolt pattern can be confusing, because depending on the type of truck you have, the dimension may be listed in inches or millimeters. 8 x 6.5 is an older pattern which was at one time used by Ford, GM, and Dodge, but now Ford and GM have moved onto 8 x 170mm and 8 x 180mm respectively, while Ram has stuck with the tried and true 8 x 6.5. Things can get confusing a bit further because some sizes are listed both ways, like a 5 x 4.5 which is the same thing as a 5 x 114.3. To make things even more confusing, when you are measuring a four, six, or eight lug bolt pattern, you measure from center to center of the studs directly across from one another, but on a five lug wheel, you measure from center of one stud to the outside of one furthest away.

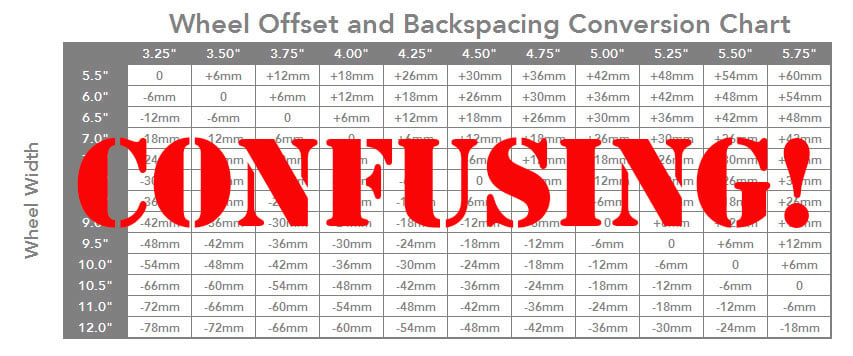

As if that’s not confusing enough already, the 3rd and 4th dimension on our sample wheel are two different ways to measure the same basic thing, and that’s where the wheel mounting surface is in relationship to the center of the wheel. Backspacing is super easy to understand, because it’s just a measurement from the back surface of the wheel to the hub, and you can easily measure that with a standard tape measure and a straightedge, and it’s always indicated in inches. Offset is really telling you the same type of information, but instead of measuring from the backside of the wheel, its measured in millimeters from the imaginary centerline of the wheel.

A 10 inch wide wheel with 5 inches of backspacing would have an offset of zero, but likewise a 14” wide wheel with a backspacing of 7” would also have an offset of 0, so the offset doesn’t tell you the full story unless you know how wide the wheel is. A positive offset wheel will be sucked in closer to the brakes and suspension, and a wheel like the Method 106 Beadlock with a -44 offset will be pushed further away from the truck and, will likely place the edge of the tires out past the fenders.

Tire Sizes Explained

For some reason, the tire industry has decided to make things extra confusing by combining both the metric and imperial measuring system into their sizes, and sometimes they make you do math to figure out how tall your tires are. Let’s take a look at two very popular sizes and break down what the numbers all mean.

Tire A:

35×12.50×18

Load Range E

Tire B:

325/60/20

Load Range F

While the numbers for these two tires seem like they are worlds apart, both are within ½ inch of each other for both height and width. Tire A is considered to be an American, Floatation or LT type tire, and it’s the easiest to measure, since everything is listed in inches. The first number is the height or diameter of the tire (35” tall) followed by the tread width (12 ½ inches) and finally the wheel size (18” diameter).

Even though this system of measuring tires is super simple and straightforward, for some reason we decided to make things a bit more complicated and introduce the metric system and long division into tires, and now if you want to figure out how tall a tire is, you better bring a calculator. Tire B is considered a metric tire, and the first number is the tread width in millimeters, and 325mm works out to be just a hair wider than 12 ¾ inches. So far, so good. The next number is the aspect ratio, which represents the relative height of the sidewall compared to its width, and finally, the last number is the diameter of the wheel, which is back in good old-fashioned inches.

To determine the diameter of a metric tire and make a useful comparison, first you need to multiply the width by the aspect ratio and then double that (325 X 0.60 x 2 = 390) and that will give you the height in MM of both sidewalls. To convert that to inches divide by 25.4 which equals 15.35”, and finally add the diameter of the wheel (20) for a final tire height of 35.4” which is extremely close to a 35×12.50. So, the question remains, why do we need both?

(Width x Aspect Ratio x 2/25.4) + Wheel Diameter = Tire Height in Inches

The one final difference between tires A and B is the weight rating, and for truck tires, the higher the letter, the more weight the tire will hold. The letter itself won’t tell you exactly how many pounds each tire can carry because it varies by size, but the letter determines how much air pressure each tire can hold, and the pressure multiplied by the surface area of the tire determines its capacity, but luckily the weight rating is always printed on the sidewall of each tire to eliminate confusion. Load range “E” tires have a maximum pressure of 80psi, and load range “F” tires carry a bit more weight because you can pump em up to a max of 95psi (however, this can vary by manufacturer, so always make sure to check the sidewalls for reassurance).

What is Right for Your Truck

So that is quite a bit of information to comprehend, but once you know it, you will be able to walk around a tire store with confidence, being able to explain any tire size to your buddies. But now that we’re out of school, how do you put this knowledge to work in the real world and pick out the right tire size for your particular truck? The short answer is research and trial and error, but there are some trends which you can follow to get into the ballpark. Each brand of truck is very different in what it can fit, so remember, these are generalities.

Most ¾ and 1-ton trucks come stock with a metric tire around 32.5 inches tall from the factory, and somewhere around 275mm wide, and normally they have a wheel with a width around 8 inches and a very high positive offset (+40 range) to keep the tires fully tucked underneath the fender. While you can easily throw a larger tire onto the stock wheels, most truck guys want a better-looking wheel that will fit a 12.50” or wider tire, so they turn to the aftermarket.

If you are building a functional off-road type of truck, traditionally you’ll want a tire with more sidewall for off road grip, so for trucks which spend a lot of time crawling through the mud, over the rocks, and in the woods, a 17 or 18” diameter wheel in a 9” width is a favorite, and usually you will pick a Beadlock wheel which has reinforcement rings around the outside which will prevent the tires from becoming dismounted when operating at a lower tire pressure. A very good looking and functional wheel for a trail truck would be the Machete Crawl from XD. It measures in at 17×9, as a slightly deeper offset of -38, and a common bolt pattern of 8×6.5 which coverers 8 lug GM trucks 2010 and older, Fords 1997 and older, and Dodge trucks up to present. If you are looking for an off-road style wheel for your street truck, likely you will pick a larger diameter because they are more stylish and have more options for tire sizing. 20 or 22 inch wheels are found everywhere on daily driven street trucks, and a Bronze Method Race 605NV looks great and can fit a much wider tire than stock with the 12” of width, but the -52 offset can be a bit tricky to fit without a little bit of help from your good friend DeWalt and Sawazall.

Ways to Make ‘Em Fit

Before you pull the trigger on those new wheels and tires, the first thing you need to ask yourself is “Am I fitting a set of tires to my truck or am I fitting my truck to the new tires?” More often than not, truck owners find themselves doing the latter, because if you limit your search to what can fit on your rig with no modifications, your options will be pretty limited, plus the finished result won’t be very impressive. If you goal is to fit slightly taller than stock tires on your truck, likely you’ll need to raise the suspension a couple inches, and the most common method is a leveling kit. It’s an inexpensive way to lift the front of your truck to the same height as the rear and is very simple to install. Most kits consist of a coil spring spacer, torsion bar key, strut spacer, or other methods to raise the truck depending on your vehicle’s suspension.

Adding a simple leveling kit can fit 35” tall tires inside the fenders on most HD trucks, but depending on your wheel offset, you may need to take a few additional measures to eliminate rubbing. The more negative the offset, the further your wheels will swing back and forth as you turn the steering wheel, and in many cases, there will be some part of the truck which interferes, like the lower valance, front bumper, or even the backside of the fenders. There are a couple ways to deal with rubbing tires, and the first is trimming. GM trucks are generally the worst for fitting negative offset wheels, and if you have a 2001 to 2014 2500HD, you’ll have to perform the “Nor-Cal” fender mod which consists of trimming back the lower edge of the front fender by a few inches to clear wider tires as you turn. Other popular areas to trim for just about every truck include the lower inside edge of the front valance, portions of the inner plastic fender liner, or in some cases the bumper itself.

While it might not seem like a big deal to attack your old beater with the cutoff wheel, if you have a later model truck with lower mileage, it might be difficult to justify cutting into pristine sheet metal, so an alternative to cutting the bumper would be installing a spacer kit which moves the stock front bumper forward by an inch or so giving just enough clearance for the tires to pass by while turning. If that’s not enough, you can take it a step further by installing an aftermarket bumper where the ends have been shaped in such a way to give tons of extra clearance. Plus, the winch mount will help get you out of trouble when the time comes.

Confused Yet?

Yes, it’s easy to get overwhelmed by all the numbers and sizes when talking about wheels and tires, but if you can figure how many turbos you should have, you can figure out a simple tire size problem. Just be sure to use your head and a tape measure, and if you consult the numerous resources online, you’ll be able to pick out a set of wheels and tires which are guaranteed to fit the first time around. Sure, you might need to massage a little metal every now and again and your wider tires may throw a little more water onto the side of your truck when it rains, but it’s all part of owning a diesel. The only mystery which may remain unsolved for some time, is who decided to combine both the metric and imperial system into our tires. That’s a person I’d like to meet…