Midway through the 2003 model year, Ford launched the 6.0 Powerstroke, and it became the new kid on the block with some big shoes to fill, as the earlier 7.3 was one of the most reliable diesel powerplants ever produced. Initial impressions were so good, in its first year of production the 6.0 was recognized with a place on Ward’s list of 10 Best Engines. However, after a few years went by, it was evident the six-liter had its fair share of issues, and it didn’t take long for it to earn a bad reputation. Although many would assume the contrary, with some thoughtful planning and careful execution, you can in fact, make a six-liter reliable. You just gotta know where to start…

Head Gaskets: Patient Zero

In its first year of production, the 6.0 was rated at 325 horsepower and 560 pounds of torque, and by the final model year in 2007, the HP remained the same, but torque jumped up a bit to 570lb.ft. In order to achieve that much power, the 6.0 had an all-new high flowing head which featured four valves per cylinder and a tremendous amount of static compression. The six-liter is rated at 18.0:1, which means there is a ton of pressure inside a running engine, and coincidentally one of the most common problems you will hear about on a 6.0 is the head gasket failing.

A head gaskets job is to keep combustion pressure sealed between the cylinder head and the piston, and out of the cooling system. Modern diesel head gaskets are made from several thin layers of steel with an embossed ridge along the outer edges, and they rely on a very specific amount of torque from the cylinder head fasteners to maintain the seal. As it happens, the 6.0 was lacking in that area: the earlier 7.3s use a 12mm bolt, and there were six per cylinder which ensures massive clamping pressure when all 18 (per side) are torqued into place. While the 6.0 used a slightly larger 14mm head bolt, instead of six, there were only four per cylinder which cuts the total number of fasteners per side to ten. On top of that, they were a torque to yield design which means they are tightened to their limit, so right off the showroom floor, the 6.0 is working at a disadvantage.

While a stock six-liter can have gasket issues, the head bolts aren’t the only problem, as modification can make things even worse. When you introduce aftermarket tuning into the mix, you’ll end up pushing your luck even further. In order to produce more horsepower, injection timing is often advanced and turbo boost is increased, both of which create more pressure inside the engine. Before too long the fasteners will stretch slightly, and the heads will actually lift off the block a microscopic amount, just enough to let combustion pressure escape into the cooling system. A dead giveaway for a head gasket failure is an over pressurized cooling system and a leak from the expansion tank cap. As much as it pains me to say, if you want your stock 6.0 to live, you’ve got to keep it on a lower power level tune until you can remedy the gasket and bolt issue.

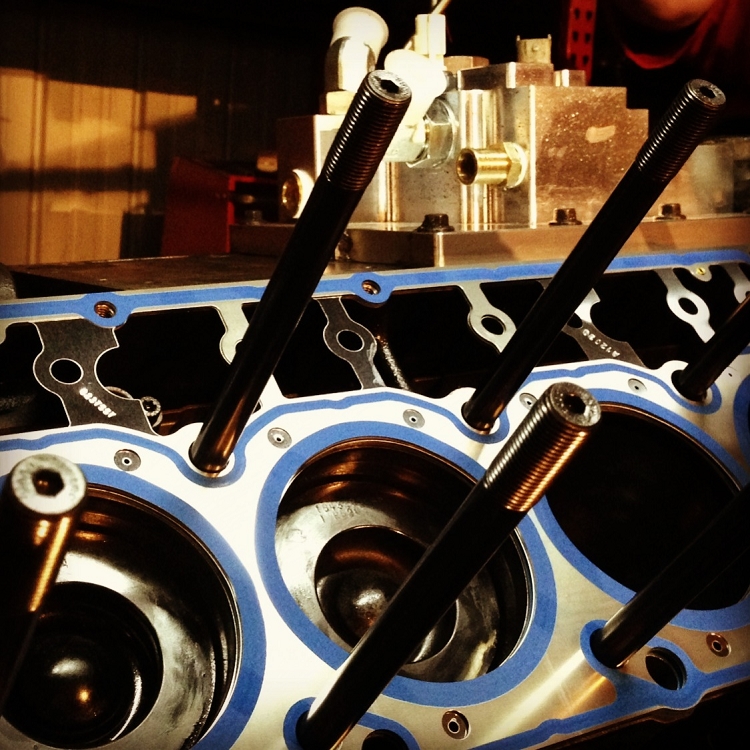

Better Bolts

If the root cause of the problem is insufficient clamping pressure on the heads, the clear solution is to clamp ‘em down harder, but it’s not as simple as just tightening the bolts. Remember, the stock hardware is a torque to yield design which means its already as tight as it can get without permanently stretching the bolt and causing a failure, and since you can’t just screw a larger diameter bolt into the engine, the only solution is to install a fastener which is made from a stronger alloy. This is where ARP comes to the rescue. Their Custom Age 625 head stud kit is the strongest option out there, and the alloy is rated at 260,000 psi of tensile strength, and when you combine that with a new gasket and a freshly machined cylinder head, even the most aggressive tuning shouldn’t give you any grief.

If you are going through the effort to install new head studs, you need to know it’s a very labor-intensive job, and many techs prefer to remove the cab off the chassis to gain access. Because the heads have to come off, you’ll want to make sure everything is done right the first time to get the most from your money. The bottom end of the 6.0 is pretty much bomb-proof, but you’ll want to get your heads inspected for cracks and worn valve guides, and have new valve seals and seats installed if its deemed necessary. When it’s time to put everything back together, using a premium gasket kit like the Black Diamond from Victor Reinz will ensure you have every last gasket and seal you need to complete the installation, and a head gasket that can cope with the rigors of high performance six-liter duty.

Keeping Your Cool

Because the HEUI system uses high-pressure engine oil to actuate the injectors, a lot more heat than usual is put into the oil. To keep temperatures under control, an oil cooler is mounted on top of the engine where coolant is circulated next to the oil through tiny passageways in an aluminum matrix. When everything is working properly, the oil should be within 10F of the coolant temp, but there is one very common failure which almost every six-liter on the planet will experience sooner or later.

After roughly 50,000 miles, corrosion in the coolant system starts to accumulate and creates a sludge which circulates through the entire engine. While a little rusty water won’t hurt most parts of the cooling system, the oil cooler is ultra-sensitive to any contamination because of the miniscule size of the passageways. It easily becomes clogged and will ultimately block coolant flow altogether. This might not seem like a big deal; you may think the only side effect is oil which runs a little warmer than usual, and that’s partially true. However, the real damage starts with the components downstream in the coolant path, and the first soldier to fall is the EGR cooler. With minimal coolant circulating through it, extreme heat from the exhaust can cause the heat exchanger inside the EGR cooler to expand and crack, and when that happens the first visible symptom for the driver would be white smoke coming from the exhaust, coolant loss, and the tell-tale odor of burnt coolant coming from the tail pipe.

This problem has a few layers which we’ll need to address one by one, and we have to work backwards to make sure we solve all parts of the problem. First, we’ll attack the symptom of coolant coming from the tail pipe. If we remove the EGR valve and perform a visual inspection and find any moisture, we know this is caused from a failed EGR cooler allowing exhaust and coolant to mix, so the obvious solution is to replace it, and because of the high incidence of failure on the 6.0, it’s a wise move to upgrade to the Bulletproof Diesel EGR Cooler. The welded tube design is much stronger than the stock finned style heat exchanger, and it has a lifetime warranty. Plus, the Bulletproof cooler allows you to leave the all-important emissions system intact rather than just deleting it. A new EGR cooler can get you back on the road, but let’s not forget why it failed in the first place, and that was restricted coolant flow due to the clogged oil cooler. An easy way to verify whether the oil cooler is at fault is easy as checking the temperature. First hook up a scan tool or gauge monitor like the Edge Insight CTS2 and look for engine coolant temp and engine oil temp. Drive around with some “vigorous” acceleration until the engine is at operating temp, and if the delta between the two exceeds 15F, that’s a sign the cooler is too clogged to do its job and should be replaced. Because it’s another labor-intensive job, you want to make sure you put some good parts back in, and this time OE is the best bet. Ford later released an updated version of the cooler which controls the oil temperature even better than the original, and it will fit perfectly in your stock housing.

If you live in the desert and regularly push your truck to the limit in extreme heat, you can take things one step further with the Bulletproof Diesel external engine oil cooler. This admittedly is an expensive upgrade and not necessary for the average commuter, but in extreme conditions there is no better way to cool off your engine oil. The stock liquid to liquid heat exchanger is eliminated altogether, and instead oil is routed from the top of the engine to the front of the grille where it’s passed through a heavy-duty radiator. Coolant flow to the EGR cooler is now increased which helps prevent failure there, and it will help your injectors last longer since the oil won’t have any chance of overheating and the oil will be cleaner with the spin on filter conversion which is included.

Even with a new EGR and Oil Cooler, we’re still not down to the root cause of the problem of this whole mess, all we’ve done is fix the collateral damage. The real cause of all this trouble is one layer deeper, and that’s filthy coolant. Of course, as part of the repair, you’ll need to drain and refill the cooling system, but you somehow need to clean things out and prevent the sludge from building up in the first place. Luckily you can buy a coolant filter kit which will prevent most of these issues from occurring. As soon as you get your truck back together, install the coolant filter kit and go for a drive. At first, you’ll want to change the filter within a few hundred miles, and then the second and third time at a 3,000 mile interval. After that, most of the sludge should be removed from the cooling system and an annual filter change will keep things tidy, and your now clean cooling system won’t be causing any more mayhem.

Crank But No Start

If you own a VT365, chances are you’ll need to diagnose a no-start condition at least once in your truck’s lifetime. While there are many things which cause this, most are related to oil flow though the high-pressure system, and the first is a restriction on the suction side. Right underneath the engine oil cooler is a tiny filter, and its job is to make sure no trash or debris makes its way into the high-pressure oil pump. The stock filter is a cotton/gauze element which can completely clog over time, starving the HPOP from oil, causing the truck to not run properly or start at all. Because of its location, it’s generally replaced whenever the oil cooler is out, and it’s a no-brainer to substitute the cotton filter with a stronger steel mesh screen, since a replacement is less than fourteen bucks.

In 2004 to 2007 trucks, the high-pressure oil pump outlet is connected to the branch tubes with a special fitting called “Snap to Connect” or STC for short. While it made for easy work on the assembly line, this flexible fitting has a hard time standing up to 4,000 psi of oil pressure at wide open throttle, and the stock part is known to fail. When it does, 9 times out of 10 you lose all oil pressure to the injectors, and your truck will just shut off. In order to start and idle, the 6.0’s injectors need to have at least 500psi of oil supply pressure, and if the STC fitting has failed, usually you’ll have 50psi or less during cranking if logged on a monitor. Ford thankfully released an updated STC fitting kit, which replaces the original two-piece quick connect fitting with a one-piece steel version which is virtually failure proof. It is slightly time consuming to replace, since the turbocharger needs to be removed so you can access and remove the HPOP, but luckily the new fitting kit costs less than $60. In the event of an oil cooler or turbo failure I always recommend updating the STC fitting since you’ve already done 85% of the labor to access it.

There are several other parts of the injection system which can cause you grief on a 6.0, namely the ICP sensor, IPR, and FICM. The Injection Control Pressure Sensor (ICP) is responsible for reporting to the computer how much oil pressure there is, and the Injection Pressure Regulator (IPR) is mounted on the high-pressure oil pump and is what controls how much oil pressure the pump puts out. When either of those fail, you will have incorrect oil pressure to operate the injectors, which can lead to erratic running and even a no-start condition. Finally, you have the FICM or Fuel Injection Control Module. This is what translates the low current signal from the ECM into a high current pulse which opens the fuel injectors. It operates at 48 volts, and because its mounted to the driver’s side valve cover in a high heat and vibration location, it is susceptible to failure. A quick voltage test on some posts inside the module will verify if its failed, and if so, a common upgrade is to install a BD-Power 58-volt FICM which will improve horsepower and fuel mileage as well as cold starts.

Maybe Ward Was Right?

Yes, the 6.0 can be a problem child. Nobody will debate you on that one, but like any proud parent, we don’t want to give up on our kids if we see potential. The six-liter has plenty of that if you can look beyond its bad reputation. Just like a kid who is acting out, you need to understand WHY before you fix the root of the problem. Yes, you need to throw a couple bucks at the truck every now and again, but if you take the time to learn why the failures are taking place, you can properly remedy the problem instead of just throwing a band-aid on and hoping it gets better. If you take care of it properly, it just might earn back that spot on the top ten engines list.

I have a 2003 F 250 and have delt with every thing that you have outlined in your well written article, Yet I still love my 6.0 Makes great power and got it real cheap from a guy that gave up on “her”!

I have a California 2004 6.0L Excursion Limited 4WD which I bought new, with the pre Jan 1, 2004 engine installed. I have used this Excursion for virtually eveything during it’s 279K miles. I was told very early by the Truck Service Advisor at the dealer never to beat or modify this engine, just drive it and SERVICE it, and don’t take it off road. I heeded his advice. Navistar took the Canadian 6.0L and made it to Ford specifications (severly short cutted to save money). The head studs, EGR, oil system, injectors, and a long list of other issues are included. I have been through a “fix” list, but nothing that really left me in one of the Ford conditions, Found On Road Dead. I WILL NOT use Ford factory parts or dealerships on this Excursion. I order parts from Diesel Power, and so does my service shop. At about 140K miles, I switched to Shell Rotella T6 Synthetic oil and everything that was getting ready to fail, magically healed. I am getting ready to drop it off because the exhaust pipes from the exhaust to the turbo have cracked. By the time they are done with it, it will probably have most of your 6.0L “fix it” list items done to it including the drop on Garrett Air Research Turbo system. I intend to keep it so it gets taken care of as well as my airplane, which I maintain myself and have it signed off. It could use some cosmetic work and a drivers seat, and the 6 CD radio finally quit, but it’s still cute. BTW, the front brakes on the Excursion diesels used the V10 gas engine rotors which is why they failed quickly. I checked the part numbers. I tried to get the Government to force a recall, but I got the standard “Ford money talks and your BS walks”. Two high performance drilled and slotted rotors and appropriate pads fixed that problem.