When you modify your diesel engine, the major parts that come to mind for most horsepower junkies are things like a bigger turbo, higher flowing injectors, a lift pump, and a hot tune. By comparison, a gasoline engine upgrade list will include parts like a better intake manifold, higher flowing cylinder heads, a performance camshaft, long tube headers, and maybe a stroker kit to increase the displacement of the engine. Whether you have a naturally aspirated gasoline engine or a turbo diesel powerplant, the name of the game is getting more air into and out of the engine and adding the appropriate amount of fuel to that air, which will create more power.

The parts we tend to purchase first and the ones that get the most attention are the things that create the power gains we’re after, but just as important (though often overlooked) are the modifications that support the amount of horsepower you want to make, and your valvetrain falls squarely in this category. You’re probably aware that valvetrain parts are available for your diesel build, but you may not know if they are needed for your build. Should you upgrade your valve springs? Do you need stronger pushrods? Should you install a performance cam? Do you need roller rockers? The truth is, it depends on your goals, and how far you want to push your engine build, but the two main factors that determine what you need are RPM range and boost pressure.

Valvetrain Basics: Meet the Team

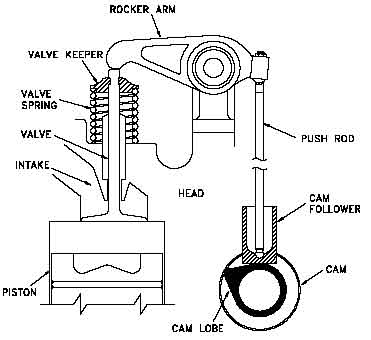

For an internal combustion 4-stroke engine to run properly, valves need to open and close at the right time to let air into and out of the cylinders. The camshaft is the “brains” of the operation, and its eccentric lobes are what control when the valves open and close, how long they stay open, and how far they are opened. Because one 360° revolution of the camshaft will open both the intake and exhaust valve once, its driven at half the speed of the crankshaft so the valves correlate to the correct cycle (intake, compression, power, and exhaust) which takes two crankshaft revolutions. A lifter rides on each camshaft lobe and translates the rotational movement into a more useful reciprocating motion. A pushrod is a thin metal tube that rides on the lifter and simply transfers the lifter’s motion up through the engine and to the rocker arm. The rocker arm connects the pushrod to the valve, and it pivots with a ratio of between 1.3:1 to 1.8:1 (depending on the engine) which means the valve opens a greater distance than the lift of the camshaft lobe. We can’t forget about the valve itself which is what lets the air into or out of the combustion chamber, and finally, the most critical part of the entire operation, the valve spring.

Valve Springs Are Pretty Important

The valve springs are the hardest working part of your valvetrain, and if they fail to do their job, the consequences could range from mildly annoying to a full-blown catastrophic failure. After the cam rotates and pushes the valve open, it must close again at the right time for the combustion process to complete. The valve spring is what’s responsible for closing the valve, but in addition, it must also push the rocker arm, pushrod, and lifter back down onto the camshaft lobe. If the valve springs are too weak or the valvetrain is too heavy, all kinds of strange things can happen. The lifter can actually jump or bounce off the lobe of the camshaft, the valve can bounce back open, or never shut at all. Also, if the boost pressure inside the intake tract is too great, it can actually push the intake valve open or if the engine RPM becomes too high, the valve spring may not be able to close the valve in time, which results in a phenomenon called valve float. A mild case of valve float can simply cause power to drop off at a higher RPM, or if it gets bad enough, the valve could make contact with the piston which means severe damage inside the engine.

So, we’ve established the importance of properly operating valve springs, but at what point should you upgrade them in your diesel? It varies of course by engine, but to me, a good rule of thumb is if you have more modifications than the basic intake, exhaust, and programmer, you should consider an upgrade. A great choice for any 24-valve Cummins from 1998.5 through 2018 would be the Hamilton 103-pound valve spring. They are a very affordable upgrade at only $325, and they will take back control of your valve train. The stock springs on a 24-valve Cummins will start to reach their limit at around 3,800 RPM or 35 psi of boost, where the Hamilton springs will allow you to go well beyond that. If you want to exceed 4,500 RPM, you may also want to install their matching valve spring retainers, which are a bargain at only $100.

Push Rods

A push rod must be strong and rigid enough to move the rocker arm and overcome the force of the valve spring, but also be light enough to not cause extra work for the valve springs. When the factory builds a diesel engine, they design components to withstand exactly how much horsepower and abuse a stock engine can dish out, and from there they try to save on material costs wherever possible to maximize profits. In the case of the stock pushrods, this means they are not particularly well suited to working with a higher RPM or greater valve springs pressure. If a pushrod isn’t up to the task of opening the valve, it will bend in the middle, and if this happens, some collateral damage may result. At the very least you’ll have a bad misfire and will be able to shut the engine down before things get out of hand, but it is possible for other mechanical damage to occur inside the engine.

A good rule of thumb would be if you’re swapping out valve springs, you probably should install a better set of pushrods at the same time since it’ll be no more work and it’s a relatively affordable upgrade to do at the same time. Manton makes some excellent pushrods that won’t break the bank and will hold up to a lot more RPM and spring pressure than your stock pushrods, and they have applications for Powerstroke, Duramax, and of course Cummins. They are available is both 3/8” and 7/16” diameter and are made from a blend of 4130 and 4135 chromoly steel and feature a proprietary heat treatment process for the ultimate in longevity and durability without excess weight.

Trunnion Upgrade

The two most popular valvetrain upgrades so far are parts that simply reinforce or strengthen the system that’s already in place, but they do nothing to increase horsepower. However, there are some changes you can make in the valvetrain that will free up power by reducing friction. The stock rocker arms on a Cummins for example, pivot on a steel trunnion and rely on pressurized engine oil to provide lubrication and reduce friction, but the tolerances are very tight, and not a lot of oil is allowed to flow through them. On a stock engine that has a relatively low operating ceiling and lower spring pressure, this usually isn’t a huge deal, but over time, friction can cause the trunnion and rocker arm body to gall, which is a cold-welding process where two metals can become stuck together. When this happens, the rocker arm becomes very difficult to move, and sometimes even seizes up completely, which can cause damage in the rest of the valvetrain. If you are in the process of installing valve springs and pushrods, take a few minutes to carefully inspect each rocker arm pivot. If you notice any resistance in the movement between the rocker arm and the trunnion, you should stop what you’re doing and order some more parts because you do not want to put the engine back together with the problem that’s brewing.

Manton makes an upgraded rocker trunnion set for 1998.5 to 2018 Cummins engines which can solve the galling problem. They have a redesigned trunnion which is made from premium tool steel, and features larger oil supply holes, wider lubrication grooves and they’ve added a few extra oil transfer grooves as well to make sure the trunnion is always lubricated. If your stock rocker arms have started to gall, the Manton trunnions even come with a refinishing kit so you can polish the galled rocker body before putting it back together.

Roller Rockers

The parts we’ve discussed so far will work great on the average street performance engine that sees daily driving use, towing, and some fun at the track on the weekends, but if you’re wanting to push your engine’s performance to the absolute limit, there are a few more upgrades you should install. If you’ve ever spent any time at a weekend car show, you will have likely heard some old-timer brag about the roller rockers on his small block Chevy, along with a three-quarter race cam and camel hump heads. While most people will write the old-timer off as crazy, there is some wisdom in his recipe. On a stock diesel engine, the end of the rocker arm slides back and forth across the tip of the valve as it’s opened and closed, which creates a lot of friction.

By replacing the solid tip of the rocker arm with a roller bearing, the amount of friction at the tip of the valve is significantly reduced, which frees up way more horsepower than you might think. I have seen dyno tests that show up to 15 rear wheel horsepower gained simply by converting a factory rocker to a roller on a bone stock engine, and upwards of 60 horsepower gained on a fully built race application. Granted, a roller rocker conversion can be a bit costly, but the benefits are much more than a reduction of friction. Valvetrain stability is extremely important in a race application where the RPM range of the engine is higher than stock, and a roller rocker setup from Manton provides an extremely rigid rocker arm design that is also as light as possible. The stock rocker arms can deflect under the load of a stiffer valve spring, increased lift cam, and higher RPM, and if the rocker arms are flexing and bending, the valves are not operating to their full potential, which means you’re leaving power on the table.

Converting to a roller rocker is not for everyone though. If you spend most of your time driving on the street, towing a trailer, or on the jobsite, and your truck still has a stock camshaft, a valve spring and pushrod upgrade is probably all you need. However, if you have a weekend warrior truck that spends all its time on the track, or a dedicated sled pull truck, you’ll likely need the added rigidity and stability of a roller rocker arm.

Camshaft Upgrade

In the gas V8 performance world, cam swaps are about as common as programmers on a diesel engine. By contrast, within the diesel community a cam swap is generally at the bottom of the list, or not even on it. There are significant gains to be had from a performance cam, but unfortunately the reason most truck owners skip over a cam swap is because of how much work and time it takes to install a cam in a diesel. On an LS engine for example, a skilled installer can have a new performance cam swapped in a matter of 6-7 hours, and have the car strapped to the dyno that afternoon getting a new tune. On a diesel though, there are so many more components in the way you have to remove in order to gain access to the camshaft. The gear train on the front of the engine is much more complex than a simple timing chain, and on a Duramax and Powerstroke, you also need to remove the cylinder heads to access the lifters, or get creative like the Cummins guys and use a wooden dowel wedged into the tops of the lifters to hold them up from touching the cam and prevent them from falling into the bottom of the engine when the camshaft is removed. Oh, and did we mention if you do drop a lifter into the depths of the crankcase, usually that means the whole engine has to come apart to retrieve it? Because of these complications, a cam swap in a Diesel pickup is much more than a weekend type of job, but once it’s in, the benefits are pretty amazing.

A Colt Cams Stage 1 street grind for your Duramax or a Hamilton 178/208 for your Cummins will move a lot more air into the engine at lower RPM which means quicker spool up of your turbo, more power across the entire RPM range of the engine, and a hefty increase in torque in the low to mid RPM ranges where you use your engine the most. In addition, you can also expect a bump in fuel efficiency and an increase of throttle response.

Just The Facts

The one great thing about modifying a diesel truck is how much power you can gain with a few external bolt-on accessories, but often this makes people forget about some of the more important hard parts inside their engine. Valvetrain upgrades aren’t required for every diesel build, but to simplify things, there are three “stages” or categories which your build will fall under which will determine what you should do with your valvetrain.

- Stage 1: If you have a mostly stock truck with basic mods like a cold air intake, exhaust, and programmer, you probably don’t need to get inside the engine to touch the valvetrain just yet.

- Stage 2: If you have a slightly larger turbo, bigger injectors, a stroker injection pump and you’re wanting a rowdy sport truck that’s still daily drivable, you’ll want upgraded valve springs and pushrods at the very least. A trunnion upgrade can help by preventing issues like galling of the rocker bodies, and a mild performance camshaft swap will absolutely benefit you in this stage and compliment all your other modifications you’ve done, but just be prepared for a fair amount of work should you decide to install it.

- Stage 3: If you are building a max effort drag truck or a dedicated sled puller, you’ll need everything. Better valve springs, roller rockers, stiffer pushrods, a large performance cam, aftermarket rocker bridges, and a better set of lifters. Because of the extreme loads on the valvetrain, no stock parts will suffice here.

The 2021 6.4L SRT engine is a beast of an engine, packing 707 horsepower and 650 lb-ft of torque. The standard transmission is an eight-speed TorqueFlite® automatic which delivers fast and smooth shifts in Sport mode.

https://moparpartssales.co/product/2021-6-4l-srt-engine/?v=920f83e594a1

Hi, you will ship Manton to California but you will no ship Hamilton Valve Springs and Push Rods? When we want the best upgrades for our trucks we are being limited to what we can buy.