When you drive one of the biggest, heaviest private passenger vehicles on the planet, are you really going to skimp on steering? The Steering linkage on the front of your truck or 4×4 is one of the most integral, yet vulnerable, systems on your truck. And that’s why a heavy-duty 4WD steering linkage replacement like Apex Chassis’ Extreme Duty Steering Kit is one of the most important modifications you can make. The ability to properly control your wheels is integral to ride, handling, and safety. And like any moving component on your truck, factory steering linkage eventually starts to wear out. But since it happens over tens of thousands of miles the steering wear and play can be something you don’t take notice of until its way past time for replacement. Of course, larger tires and wheels only compound the wear and vulnerability issues for steering linkage. Even if the tie rods ends are still good, constantly realigning a truck with a weak tie rod and drag link can be tiresome. That’s why the minds behind Apex Chassis came up with complete Extreme Duty Steering Kits for Ford Super Duty’s and Ram trucks. With replaceable forged steel HD tie rod ends threaded into .300 wall DOM SAE 1020 links, this is the last steering system you’ll ever have to purchase for your prized rig.

Can I Install This at Home?

While we are doing our Apex Chassis steering linkage install on a lift, this is an easily-accomplished install by any fair-weather mechanic at home with some good wheel chocks in place. We chose a Super Duty with a high-clearance Mercenary bumper that exposes the steering linkage more, but all Apex Chassis parts fit onto the specified vehicles without modification or the addition of other parts.

Extreme Duty – Stronger and Less Prone to Wear

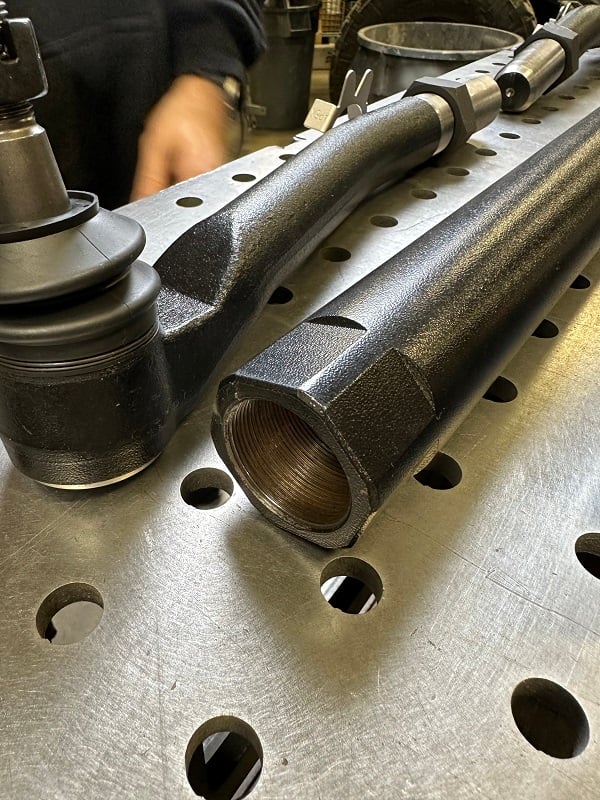

Factory tie rods and drag links are often small diameter or thin-walled links, bending and possibly buckling under the force of heavy tires and wheels—especially when off-road. And located forward of the front axle, a tie rod can be one of the most easily damaged integral systems on your truck. Apex Chassis’ replacement drag link is a massive 1.75 inches diameter and the tie rod measures at 2.125 inches—both .300 wall DOM SAE 1020 tubing. Combine that with steel forged tie rod ends with chromoly ball studs and the Apex Extreme Duty Steering Kit is the toughest steering link you can bolt in front of your axle. If that’s not enough, Apex Chassis offers a limited lifetime warranty on their parts.

Keep It Pretty With a Long-lasting Finish

While its no surprise the Apex tie rods and drag links have a nice black E-coated finish that keeps them looking good for a long time, tie rod ends are also treated with a durable E-coating that covers the threads as well.

OE Replacements That Bolt Right In

Apex Chassis does not try to reinvent the wheel. While the tie rod ends and links are stronger in every way, they mimic the OE design & link placement and bolt into the tapered knuckles and pitman arm just as the OE parts do.

Assembly Takes Minutes

With precision rolled threads on the ball studs and step threads to easily start the nicely machined pieces at every point, the loose assembly takes just minutes. A little bit of anti-seize on the threads of the tie rod ends can make future alignment adjustments much easier. And to make it even easier, Apex Chassis machines its tie rods and drag links so you can get a wrench end on them.

More Angularity for Increased Travel

Apex Chassis was sure to build more angularity into the drag link tie rod ends than the OE drag link ends allow. This allows the drag link to reach a more severe angle before maxing out, accommodating aftermarket long-travel suspension that can drop the axle further away from the frame than the factory suspension allows.

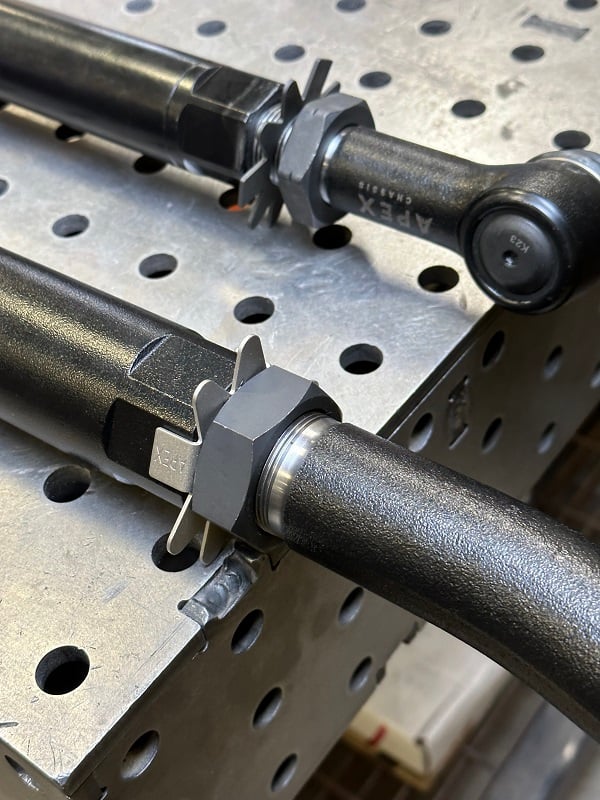

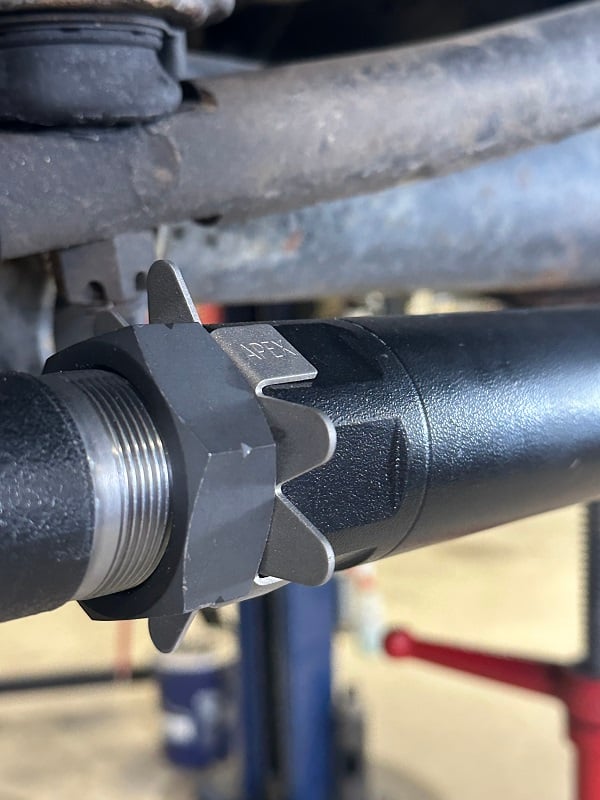

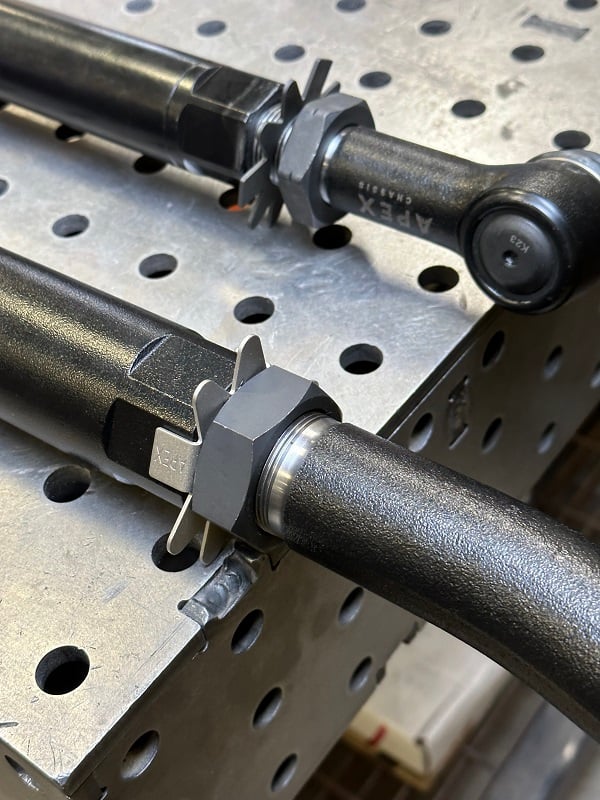

Jam Nut Locking with Ninja Washers

To ensure there is no movement at the tie rod ends that can lead to misalignment, Apex Chassis came up with the Apex Ninja Washer. The alternating tabs on the Ninja Washers bend down over the links and jam nuts to negate any bit of movement that would allow the jam nuts to back off.

Replaceable Ends At Every Point

Unlike factory linkage, every end on the tie rod and drag link of the Apex Chassis Steering Kit is replaceable. You may end up wearing your truck out before you wear these ends out, but if you somehow damage or wear out a part, you won’t have to buy a whole new kit.

Retrofitting Starts With Removal

With the truck up in the air or the wheels chocked on the ground (parking brake on), you can remove the cotter pins and unthread the castle nuts on the factory tie rod ends at the knuckles and pitman arm. Hopefully your truck hasn’t acquired too much rust and gunk that would keep the original ball studs from popping out after a few hammer taps (blows).

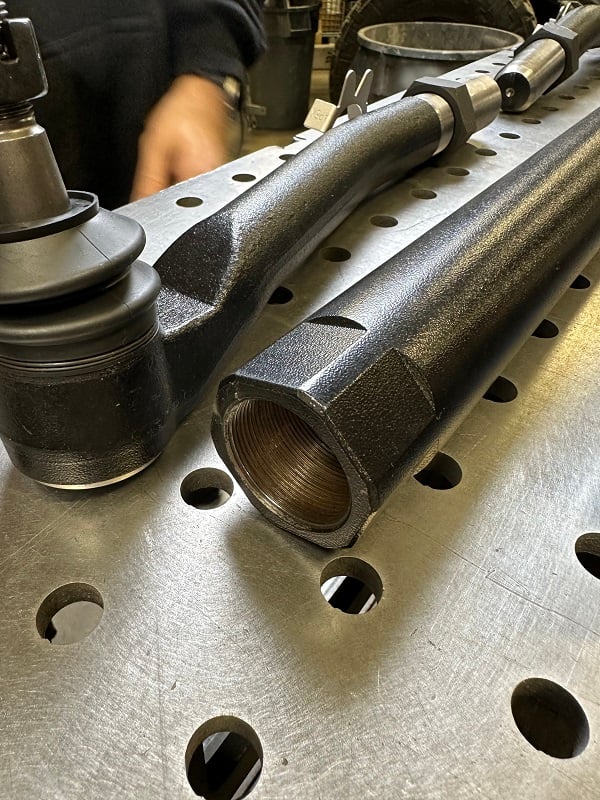

Stock Vs Apex Ends—Judge For Yourself

A quick peak at the Apex Chassis equipment compared to the OE stuff shows a clear size advantage. The SAE 1045 solid steel housings of the Apex tie rod ends hold SAE 4140 hot-forged chromoly ball studs, are predrilled for zerk fittings, and have gull winged grease grooves for improved lubrication disbursement. CR rubber boots are used to keep in the grease and keep out exterior elements.

Order Links Separately

The Apex Chassis Extreme Duty Tie Rod and Drag Link are not dependent on each other and can be purchased separately. You will save a few bucks by purchasing them together as the Apex Chassis Extreme Duty Steering Kit, though. Once the OE tie rod and drag link are off the truck, try to mimic the same lengths with the new Apex linkage. You will still need to align it, but this will get you to the alignment shop.

Reversible Drag Link

The Apex Chassis Drag Link is reversible to accommodate suspension systems that use a flipped pitman arm setup. They accomplish this by drilling the steering stabilizer mount hole straight and including a reversible stainless steel tapered sleeve so the steering stabilizer can be mounted on either side.

The Final Steps

With the Apex Chassis Steering Kit loosely installed on the truck, tighten the ball studs into the knuckles with the included castle nuts so it is solid and then use a tape measure and a friend to get an equal measurement at the front and rear of the tires, threading the tie rod in or out to reach the desired alignment. Once this is done, we’d suggest tightening the jam nuts and heading to the alignment shop before banging down the tabs of the Ninja washers. That being said, the Ninja washer tabs are semi pliable and can be bent up or down more than once. Let the alignment shop know that Apex Chassis recommends torquing the jam nuts upwards of 200+ ft lbs to get them secured.

Time For Alignment

With the Apex Chassis steering linkage tightened up and aligned as best as possible, it should be time for you to head straight for the nearest steering alignment shop. Assuming your truck’s axle was previously set with the correct caster and you did not modify the suspension in any way, the alignment shop should only need to check and address the toe in/toe out affected by the tie rod and the steering wheel position affected by the drag link.