Every now and again, a new product comes along which disrupts the status quo and totally changes the way we think about a particular segment of the market. In the world of fast food, the current trend of meatless alternatives is exploding, and while I don’t personally subscribe to the idea of eating deep fried impostor patties of nuts, soy, and kale, I do like modifying diesel trucks. When I heard the crew at Banks Power was designing a new differential cover, I knew it would be more than just another blingy accessory, because a product doesn’t get to wear the name of Gale Banks unless it truly does what it claims.

Oil Gets Hot…

Here’s a fun fact to think about: any time you do work by transferring energy from one object to another, you’ll get waste heat as a byproduct. This is especially true in any mechanical device like an engine, transmission, braking system, and especially a ring and pinion gearset. A massive amount of torque enters your rear axle from the driveshaft, and it’s met with resistance on the other side from the tires and the weight of the truck and whatever cargo is attached. The vehicle only moves when the amount of force being applied to the axle is greater than the drag, and because of this constant struggle (and the laws of physics), the hardened steel gears will get very warm under normal operation, and the level of heat will go up as the amount of work increases.

In order to prevent the metal gears from getting too hot and grinding themselves to dust, manufacturers use a thick oil to lubricate and cool down the ring and pinion. Under light operating conditions like cruising down the highway unloaded, the fluid inside your differential might only get as warm as 135 degrees Fahrenheit, but if you are sustaining a much higher load like hauling a pair of Skid Steers up Dead Man’s Pass, the temperature of the gear oil in the rear end can reach 300 degrees or more. While this may not sound extreme, it is quite a bit warmer than the ideal 150 to 200 degree range. As your gear oil spends more time at higher temperatures, it will chemically break down and provide less lubrication, and if left un-checked the excess heat can cause unnecessary wear of your gears and bearings. One thing we can all agree on is cooler oil is better, and manufacturers do specify more frequent fluid change intervals under severe operating conditions to compensate for overheated oil. The best thing you can do to extend the life of your differential parts however, is to keep the temperature under control.

Fluid Dynamics 101

Engineers and designers have been struggling for years to keep the temperature of automotive fluids regulated, but differentials are uniquely difficult to keep cool. Your engine and transmission both rely on oils for lubrication and cooling, and they each also use an oil pump to move the fluid around from place to place. Your engine for example, uses an oil pump driven by the crankshaft, and pressurized oil is sent to the main bearings, rod bearings, the camshaft, valvetrain and more, and if the oil gets too hot, it’s very easy to tap into the oil supply circuitry and divert some of the oil to a heat exchanger where the extra temperature can be removed. This same exact concept can be applied to an automatic transmission, but one unique thing about a rear axle is there is no pressurized oiling system to tap into, which means no external heat exchanger for your gear oil.

The carrier and wheel bearings on a solid axle sit just below the surface of the oil, so as they spin, they get coated in lubricant, however the pinion generally sits farther frontward and above the level of the oil. Because the lower third of the ring gear is submerged in an oil bath, it creates a paddle wheel like effect as it turns, and when moving at road speed, it grabs the oil and flings it up and around to the front of the axle housing where a small passageway guides the oil to the pinion gear and bearing. It’s quite an ingenious design, and you can probably guess there is a whole team of engineers whose only job is to precisely calculate the shape and position of that little window to get just the right amount of oil up to the pinion bearing. Believe it or not, the shape of your stock differential cover also has a huge effect on how well the lubricant gets dispersed.

Don’t Sweat It

Likely due to cost saving measures and ease of manufacturing, the stock differential cover in most pickup trucks is made from a single piece of stamped steel. They are durable, inexpensive, and more than strong enough for the task at hand, but by nature steel doesn’t conduct heat very well. Carbon steel has a thermal conductivity rating of 45 watts per meter per kelvin, but aluminum comes in at a whopping 237, or about 5.25 times greater thermal conductivity than steel. Basically, aluminum is much better at transferring heat, and in certain pickup applications where the axle may be subjected to higher fluid temperatures, the OE’s have occasionally chosen finned cast aluminum for their differential covers.

The aftermarket has followed suit, and there are tons of aluminum covers on the market with a range of touted features, like extra fins to increase cooling capacity, main cap support screws for increased strength, flashy brand logos, and of course an increase in fluid capacity which comes from two different areas. The first is the physical size and shape of the cover: most popular styles use a flat-back which is spaced further away from the ring gear allowing more oil volume, and the other method of adding fluid capacity is to raise the fill level over stock. If you have a 3rd or 4th gen Ram or a 2001 and newer Duramax, you’re going to have an AAM (American Axle Manufacturing) 11.5” rear axle, which has a factory fill spec of right around four quarts, but when equipped with an aftermarket cover, the capacity is raised in some cases to nearly two gallons. But is all that extra fluid a good thing or even necessary?

Problems with Existing Products

As Gale Banks started the development process for his new differential cover, he first had to find out if there were any shortcomings from the options which were already on the market, and the first thing he did was perform some real-world testing. Using a pickup outfitted with more instrumentation than the first lunar lander, Banks collected mountains of data, and it can be broken down into a few distinct findings, and the first is a fundamental problem with the flat-back design. Most stock differential covers are slightly dome shaped, but they have a bulge which closely follows the contours of the ring gear, and as it turns out, it’s done that way on purpose.

When you swap to a flat-back style diff cover, the once gradual fluid pathway is now disrupted with what is essentially a brick wall, and instead of smoothly being pushed up and around, the gear oil crashes and tumbles and falls away, and much less of it makes it to the critical bearings which means accelerated wear from a lack of lubrication. While this is less than ideal, the point which struck home for me was how much extra drag is created by this turbulent oil, and the real-world cost to it can have on your wallet. Banks found that a flat-back diff cover would cost you another $447 in fuel over 100,000 miles simply from the extra drag of the turbulent fluid. The next major problem discovered was with the claims of increased heat rejection. Many manufacturers have added some sort of raised fins to increase the surface area of their cover and aid in heat rejection, and all the cast aluminum covers did cool the fluid better than a stock stamped steel version. Unfortunately, there isn’t much extra airflow around the back of the differential cover to truly take advantage of the fins.

The final problem spotted was the extra fluid depth which is sometimes added by aftermarket covers. While gear oil is critical to cooling and lubrication, there is such a thing as too much fluid in your axle. From the factory, the process is to remove the fill plug, and add fluid until it starts to flow out, and usually that level is just high enough to allow a bit of oil to flow into the axle tubes and out to the wheel bearings. The ring gear will be submerged on the bottom with a slight portion of the carrier as well, but most of the differential assembly is above the static level of the fluid. Some aftermarket differential covers add capacity simply by raising the fluid level, but the problem with this method is more of your ring gear and carrier are submerged in thick oil which creates extra drag on the rotating parts and aerates the fluid which decreases lubrication.

The Right Solution: Banks Diff Cover

With the results of the test data in-hand, the team at Banks knew there was room for improvement, so they set out to build the world’s best differential cover. First, it needed to be able to keep the temperature of the fluid as cool as possible during steady state driving, and whenever the fluid warmed up from harsh conditions like towing up hill, the cover needed to be able to bring the temperature of the fluid back down quicker than the competition. Most importantly, their cover needed to have proper fluid dynamics inside to prevent aeration and provide the best lubrication to the pinion bearings, and they wanted to do this all without adding extra fluid.

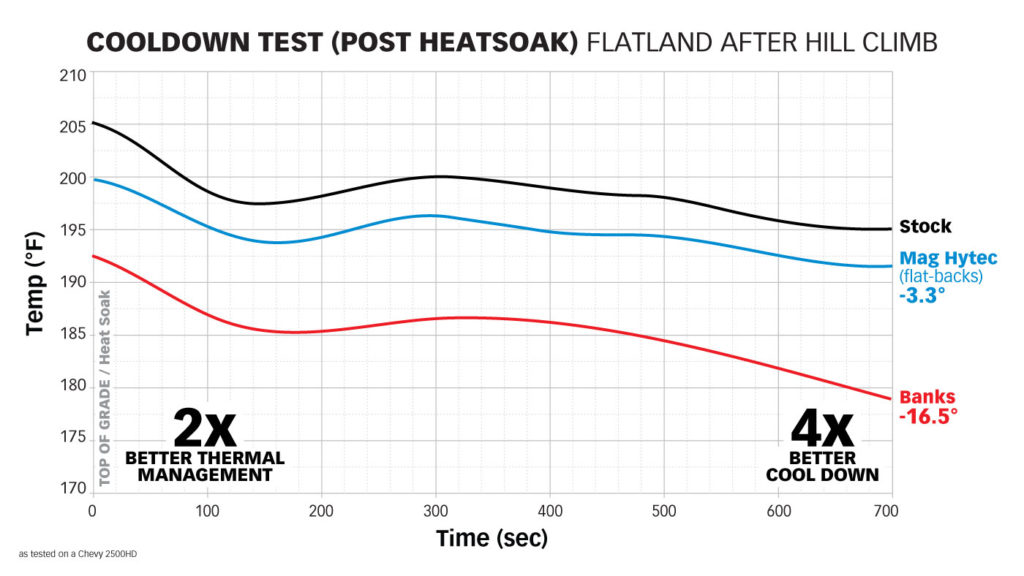

You’ve likely seen pictures by now, but what they came up with looks nothing like any differential cover you’ve seen before, and its design and function is so unique they were awarded a US Patent. The most notable visual part is the ram air scoops which sit on the bottom and grab air rushing underneath the axle and guide it up and over the back of the differential to greatly increase the transfer of heat energy away from the differential. On the inside of the cover there are several more fins which serve two purposes: first is to remove more heat from the oil, but the second use of the fins is as a fluid guide. Immediately behind the ring gear are some radial grooves called the “lubricant raceways” which help guide the oil up to the top of the differential and on its way toward the pinion, and on the sides of the cover are some guides which direct fluid towards the axle bearings to promote lubrication. When it was all said and done, they had created the Banks Ram-Air Differential Cover which has over four times the surface area than stock for external heat radiation, and in testing was found to keep the fluid 61 degrees Fahrenheit cooler than a stock during an hour long test. After a hard run up a mountain pass, the gear oil was much cooler as well, but on the way down the Ram-Air diff cover cooled the fluid even quicker as well. Basically, it keeps your rear axle calm, cool, and collected, and does it without using any extra fluid over stock, increasing wear, or decreasing your fuel mileage. When you install your Banks differential cover, it’s the perfect opportunity to give the axle housing a thorough bath with brake cleaner and inspect all the bearings and gears for any signs of wear. When it comes to filling your Ram-Air Cover, you’ll need four quarts of gear oil, and Schaeffer’s Synthetic 75w-90 will be the perfect complement to your new rear diff cover.

All the Way to The Banks

Gale Banks is a pioneer in the diesel high-performance industry, and today he continues to innovate with new products like the Derringer Inline Tuner which can add up to 81hp and 144lb.ft. of torque to your 2020 Duramax L5P, and of course many more emissions intact performance parts which are 50-state legal. My favorite part is there is no speculation or wild claims about performance gains to be had. Their promises are as good as cold hard cash, and you can take that to the bank.