If you haul a heavy trailer regularly and prefer shifting gears on your own timetable, chances are pretty good you own a Cummins powered Ram. While GM and Ford both offered a few manual transmissions behind their Powerstroke and Duramax engines, the vast majority came attached to an automatic. Ram is king when it comes to manual transmissions and diesel pickups, and that trend started way back in 1989 with the Getrag G360 5-speed manual. In 1994, Ram switched things up and implemented the New Venture NV4500 5 speed manual which was a fair amount stronger than the Getrag box, although it was known for having its own quirks. A couple years later in 1999, High Output 24v Cummins trucks got an upgrade to the NV5600 manual, which was still made by New Venture, but this new trans was even stronger and had six forward gears. That lasted until midway through the 2005 model year, when Ram equipped their trucks with a brand new G56 six-speed manual transmission, and this time the manufacturer was Mercedes. While this may seem like an odd pairing at first, you must remember at the time Daimler-Benz owned Chrysler, so the industrial strength German gearbox was available to Chrysler to use. Even though their partnership formally ended in 2007, Chrysler still was able to use the G56 in its Ram trucks until 2018.

A Different Animal

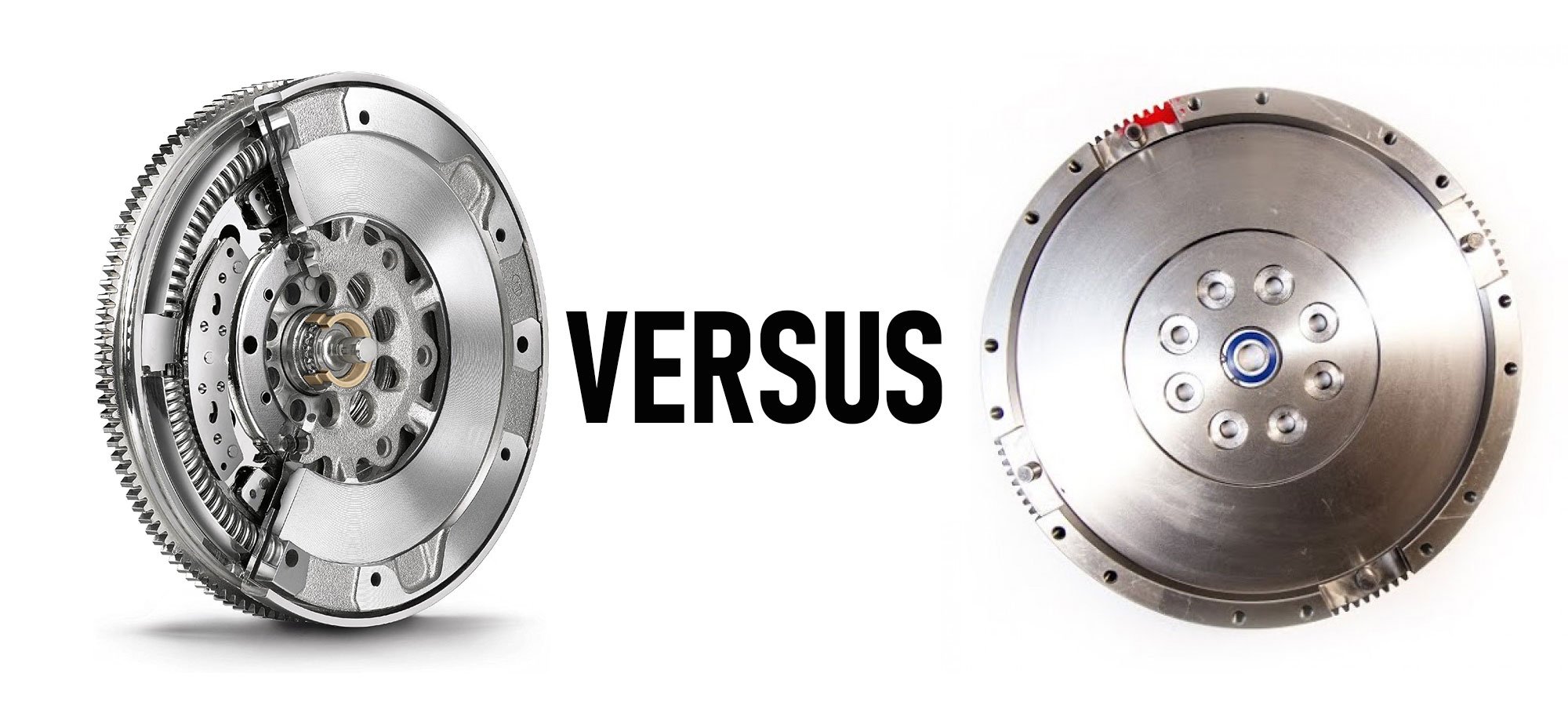

One major difference between the G56 and its predecessors was the material it was built from. The Getrag and New Venture manual transmissions were all made with cast iron construction, but the G56 was made from aluminum. While this did make for a lighter weight transmission and likely reduced manufacturing costs, one drawback of an aluminum case is it doesn’t absorb quite as much noise as its cast iron counterparts. This was a problem for the NVH (Noise-Vibration-Harmonics) department, since most drivers who purchase a brand-new truck prefer it to be as quiet as possible. In an effort to make their new Ram trucks meet buyers’ expectations, the engineers decided to try out a method which other manufacturers had used in the past with mixed success: a dual mass flywheel.

Different Types of Flywheels

A conventional flywheel is a very simple part: it’s essentially a flat round piece of steel that bolts to the back of the crankshaft, has some teeth on the outside for the starter to engage, and a flat machined surface on the back for the clutch disc. Conventional or single mass flywheels have been widely used since the dawn of the automobile, but in certain applications like a high-compression and high-torque diesel, the single mass flywheel does very little to dampen any vibrations coming from the engine.

Each time a cylinder fires on its power stroke, it produces a sudden shockwave that is transmitted directly from the piston into the connecting rod, and finally into the crankshaft where it is quickly accelerated. But each time a piston approaches top dead center on the compression stroke, the force of squishing all that air works to slow the crankshaft’s rotation. Of course, the power stroke always wins (which is why an internal combustion engine runs in the first place) but effectively the crankshaft is constantly being sped up and slowed down all at the same time, even when the engine is idling at a steady RPM. As you can imagine, this constant internal battle does produce quite a bit of vibration and harmonics that need to be dealt with.

The dual mass flywheel Ram decided to implement in the war against vibration was (in theory) a win-win, and it does an excellent job of stopping vibrations from the engine being transmitted into the transmission. It’s made from two major parts: the first bolts to the crankshaft and has the starter ring on the outside, and the second half is the flywheel itself with the machined surface the clutch disc grabs onto. Both halves of the flywheel are isolated from each other with a series of heavy-duty arced springs, and in normal operation the springs allow each half of the dual mass flywheel to move independently from one another, and this dampens any vibration and makes for smooth and effortless power transitions and gear shifts.

In the real world however, the Chrysler DMF proved to be problematic, especially if additional horsepower was added to the engine. There are many small parts that can fail, and when they do, the two halves of the flywheel will be allowed to rattle back and forth, without the proper dampening of the springs, and the driver will notice additional noise and vibration, especially as the engine is shut down. If left unchecked, this vibration can cause other problems, like a worn input bearing on the transmission, worn pilot bearing, a leaky front seal on the trans, and in extreme cases, a cracked rear engine adapter plate or bellhousing.

Opportunity for an Upgrade

While a failing dual mass flywheel can be a costly repair if the symptoms are ignored, it’s not all doom and gloom. On average (with stock power levels) a dual mass flywheel can usually make it to 100,000 miles before it goes out, and normally by that time the stock clutch disc will be worn out and needs to be replaced anyway. As long as you make the repair at the first sign of trouble and don’t let the vibration get out of hand, you should be able to avoid any collateral damage caused by a failing DMF, but it’s a good opportunity to eliminate any causes for problems down the road.

If your truck is stock and you don’t plan on adding any extra horsepower or towing at maximum GVWR all the time, a great option is the Valair Single Disc Stock Replacement Solid Flywheel Clutch Kit. It eliminates the DMF and replaces it with a traditional single mass flywheel, which means zero chance of failure. The Valair kit comes with an organic clutch disc and a pressure plate that offers smooth engagement and a stock clutch feel. In addition to the flywheel, clutch, and pressure plate assembly, the Valair kit also comes with the necessary hydraulics you’ll need to properly actuate your new clutch package, since by changing to a single mass flywheel, the spacing on the throwout bearing will be different.

If your truck is modified with a hot programmer, larger turbo, or bigger injectors and you tow a lot, likely you will experience a failed DMF and clutch much sooner than 100,000 miles. In this case, it will be a smart move to get rid of the dual mass flywheel, but an organic single disc clutch won’t provide enough holding power for your application. In this case, it’s prudent to step up to a multi disc clutch to double or triple its holding power. A twin disc clutch uses two friction discs separated by a steel floater plate, but it attaches to a standard single mass flywheel so you can still eliminate the stock DMF. Both Valair and South Bend Clutch offer great options in the twin disc category, and you can expect them to hold around 600 horsepower and be suitable for towing up to 30,000lbs, which is about as much clutch as anyone will ever need. The great thing about a twin disc clutch is it can hold more torque without needing to use extra grabby friction materials or an extra strong pressure plate that will make for increased pedal effort. Basically, a twin disc clutch drives and engages like stock, but holds a lot more power.

New Strange Noises

So far, it sounds like swapping from a DMF to a traditional flywheel is a win-win with zero downsides, but, before you get out the credit card and yank the transmission out of the truck, there are a few things you’ll want to know. First and foremost, is noise: one of the main reasons a DMF was used in the first place was to dampen sound and “gear rollover” noise coming from the transmission, and when you convert to a fixed flywheel, your transmission will get much noisier, and sometimes it can even sound like something is broken or worn out. Gear rollover noise is caused by the normal pulses and torque spikes that come from the engine and is usually most noticeable at low RPM high load driving, or even at idle. When driving a G56 that’s been converted to a single mass flywheel, usually its recommended to downshift a gear so the RPM raises slightly to avoid “lugging” the engine, and when you shut it down, keep the clutch pushed to the floor to isolate the transmission from the engine. While these habits can help to avoid the zones where the sound is worst, it’s important to understand that the extra noise with a single mass flywheel is totally normal, although many people can’t stand it after driving a stock DMF. In addition to the noise from a single mass flywheel, if you’ve upgraded to a twin or triple disc clutch, there will be additional noises you will hear when the pedal is pushed in. When the clutch is disengaged, the steel floater plate will essentially be rattling around, and it does make a fair amount of noise. While this will be shocking the first time you hear it, rest assured it’s a totally normal sound for a multi disc clutch.

Turn Down the Noise

Thankfully, there are some things you can do to keep the new gear rollover noise to a minimum, and the first is a simple oil change in the transmission. The G56 is somewhat picky about what fluid it uses, but Hotshot’s Secret has formulated a blend of their Blue Diamond Transmission Fluid specifically for the G56 to help reduce rough shifting and gear noise. One more step which is recommended by many G56 owners to further reduce noise is to overfill the transmission by one quart which keeps more of the gear train submerged in oil and running quietly. This practice does require you to remove the shifter tower to pour in the additional quart, but that’s also a good opportunity to replace the inner shifter boot which can crack as it gets older, or even to upgrade to a B&M Precision Shortshifter.

As we discussed earlier, the root cause of noise from the G56 is vibration from the engine. The stock dual mass flywheel did a good job of isolating the engine from the transmission, but there is another way to achieve a similar result. Every engine has a harmonic balancer installed on the front of the crankshaft, and while it may look like a simple pulley, it does a lot more than turn a belt. On a stock balancer there are two separate halves made from heavy steel, but they are isolated from each other with a piece of rubber. This does a fair job of reducing the torsional vibrations from the engine, but a better solution does exist on the aftermarket. A Fluidamper Harmonic Damper replaces the stock harmonic balancer on the front of the engine, but its fluid-based design does a much better job of absorbing vibration from the crankshaft, and will result in a smoother and quieter running engine, which translates into less noise from your G56 as well.

What’s The Best Option?

Unfortunately, it’s rare to be able to have your cake and eat it too, and clutch and flywheel selection for your G56 is no different. If you demand an ultra-smooth shifting and noise free transmission, you will be stuck with a dual mass flywheel and stock clutch. When it does wear out, you can either go with a Mopar OEM replacement, or there are some good aftermarket options for a replacement dual mass flywheel like from LuK. However, keep in mind a stock replacement clutch and flywheel are only good for stock power levels so forget about running a +100hp tune.

If you want to run a stock power level and you don’t mind a little extra noise, but you want to eliminate all possibilities of a DMF failure, then a solid flywheel and an organic single disc clutch will get the job done. You’ll get smooth engagement and a stock pedal feel, but with the added reliability of a single mass flywheel, and with a few simple tweaks you can minimize any noise or vibration.

Finally, if you want a lot of extra power and you tow with the truck, then you absolutely need to upgrade your clutch game. No ifs, ands, or buts, the stock setup will not do. You need a twin or triple disc clutch to cope with the massive amount of torque the Cummins can produce, but as long as you select a clutch material and pressure plate that matches your power level, you can still have a relatively smooth engaging clutch without requiring tremendous pedal effort.

G56 Life Expectancy

The question of how reliable is the G56 manual transmission comes up from time to time, and overall, it’s a very strong transmission and has been proven behind many 600hp trucks and has even been pushed to 800hp a handful of times with varying amounts of success. From a high performance or racing standpoint, a manual transmission equipped diesel may never be the perfect choice, regardless of who makes the transmission, simply because of how slow shifting they are. You’ll never be able to “powershift” an NV4500, G56, or NV5600 the way you can a Corvette or Mustang, but that’s not what they were designed to do. They were built to tow and haul lots of weight, and last for hundreds of thousands of miles. The weakest link of the G56 is by far the clutch and flywheel, but as long as you address the issues before they cause other damage, the G56 will give you a lifetime of reliable service.

Hi is it a good idea to install fluid damper if you have a nv 5600 transmission?

I did the single mass dual disk conversion. It is noisy but that is not the issue. When towing a heavy trailer, sometimes I need to go back and forth a few times to back into tight spots. When doing this, my clutch disks will stick and I can’t shift into reverse. I have to shut off the engine and shift it, then start back up. Kind of a pain.