Written By: Lawrence “LT” Tolman

One of the facts of life I’ve learned over the years is there’s always a tradeoff of some sort to be made with every decision. Some of us take a very methodical approach, make a pros and cons list, and carefully select the best option, while others just jump in headfirst and make decisions based off emotion, gut feel, or what their cousin told them to do. While that may be fine for picking out where to take your significant other to dinner, when it comes to modifying your truck, the former approach is often wisest. The more research you can do, the better informed you will be, and you’ll wind up with a much more well-rounded project. If you take the shoot first ask questions later approach, the consequences can be pretty expensive, and you might find yourself needing a new engine. One of the great things about modifying a diesel truck is you can have a powerful and reliable setup, the trick is knowing what parts to select.

More Power

Have you ever wondered exactly how a diesel engine is modified and tuned to make more power? The concept is fairly simple as it turns out. All you need to do is inject more fuel, and mix that additional fuel with more air. This results in a bigger explosion which will push down the piston with more force, and of course that big smile on your face when you smash the loud pedal.

With the use of electronics, both the air and fuel side of the equation can be changed to some extent. A calibration change via a tune, programmer, or inline module will adjust the pulse width (on time) of the fuel injector and raise the fuel pressure in the rail, both of which allow a greater volume of fuel into the cylinder. When a tune alone is not enough, the stock injectors can be replaced with an aftermarket set which has larger holes to allow an even greater volume of fuel through, but of course you’ll have to support that increased flow with a larger or additional injection pump and a higher capacity lift pump. The air side of the power equation can be handled electronically to some extent as well. By manipulating vane position and fueling it harder, the stock turbocharger can push more fresh air into the engine, but additional parts like a cold air intake and free flowing exhaust will also be needed to get more air into and out of your engine.

Here’s the rub: just like in algebra 101, things need to be balanced. If you’ve stacked together an inline programmer and a flash tune, you’ll wind up with way more fuel than air, and a ton of injection timing. The air fuel mixture will be too rich, your EGTs can go through the roof, and you can possibly wind up with a cracked piston, which is the opposite of reliable. If you take the opposite route and slap on a giant turbo, you might be able to make a lot of power, but when the head gasket gets blown out, you’ll likely be wishing you hadn’t made that impulse buy on the go-fast goodies.

The Variables of the Equation

I like to classify parts into two categories: ones that ADD horsepower, and ones that SUPPORT horsepower, and if you can better understand how the parts function, you can better decide which is right for your goals. If you want your truck to be reliable and powerful for many years to come, you can certainly throw on the power adding parts, but you’ll also need to spend a lot more time with parts in the power supporting category, and the best bang for the buck comes from parts that do both at the same time.

TUNING: We’ll throw tuning on the top of the list, since it’s likely the first modification people will purchase. On the surface, it’s easy to think all tuning is the same, but there is a lot that goes into making a powerful and reliable tune. The great thing about late model diesels is you have the option for a selectable tune with several different power levels, and you can switch back and forth with the touch of a button. For daily driving, most trucks get the best fuel efficiency on a tune which adds somewhere around 120hp over stock, but you’ll want to adjust the tune depending on your conditions. If you have a heavy trailer on the back (8,000lbs and up), you’ll want to dial the power back a few notches. Most towing tunes add somewhere around 45-60 extra horsepower, which will keep your EGTs under control when hauling up a steep grade, or any time you have to be on the throttle for a sustained amount of time. The goal of a good tow tune is to create less stress on the transmission and entire drivetrain, and as an added bonus, if you have an earlier model truck equipped with a VGT charger, turbine braking can be activated which will help slow your truck down while helping your service brakes last a bit longer.

The last thought about tuning is what power level to pick for the maximum setting. Many custom calibrations give you the option for a power level which is quite a bit spicier than stock transmission can handle. Earlier model trucks like the LB7’s and LLY with the 5-speed Allison can easily be tuned well beyond the capability of the stock transmission, so be conscious of what tune you purchase, and how you drive the truck. And finally, don’t tow on the hot tune. That’s just asking for trouble…

EXHAUST/INTAKE: The airflow pathway in and out of your engine begins at the air filter and ends at tail pipe, and the whole thing needs to be addressed to add power and reliability. As we all know, cooler, denser air has the capacity to make more horsepower, and when you combine that with a less restrictive pathway, you get lowers EGTs which is one of the most important things to have on a diesel. A cold air intake minimizes restriction and allows more air into the turbocharger (at a cooler temperature). On an LLY Duramax for example, the stock turbo intake horn (not part of most cold air intake kits) is actually so restrictive it can lead to engine overheating issues, so it’s an especially important upgrade. An easy upgrade like the S&B turbo intake will give smooth and unrestricted flow into the turbo and goes a long way to adding reliability, and keeping that Duramax running at the proper temp.

After the air leaves the turbocharger, it’s a lot hotter than ambient temperatures (sometimes a few hundred degrees) which is no good for power or reliability. All late-model diesels pass the pressurized air from the turbo through an intercooler (also known as a Charge Air Cooler, or CAC for short) which peels away the extra heat. When running a performance tune, the turbo can be pushed near its limits, and will be making a lot more heat than stock, and the factory intercooler may have a hard time moving the volume of air and taking away enough heat. A more efficient replacement from Banks Power can solve all those problems on a stock or tuned truck. It will pull more heat out of the charge air, it can flow a greater volume of air with less restriction, and for you Duramax guys, it will eliminate the plastic end tank which is a weak point at an elevated power level.

Once the combustion process is complete and air is burnt in the engine, it has to pass through about 15 feet of pipe and a restrictive muffler before it exits to atmosphere. By increasing the diameter of the stock exhaust to at least four inches and utilizing a free-flowing muffler, restriction is minimized, power is increased, and at the same time your EGTs are lowered. When it comes to airflow, you want to touch every part of the path you can: cold air intake, intercooler, Y bridge, down pipe, and exhaust. The simple mantra to remember is “more air, more better, more power”.

TURBO: The turbo is clearly an important part of the airflow pathway, considering it’s what’s responsible for producing boost and forcing it into the engine. While its hard to go too big on any other part of your engine’s airflow, a turbo is a different story, and its size is directly related to power potential and engine longevity. If you go too big here, you’ll be giving up a lot of drivability, and increasing lag and exhaust temp at lower engine speeds. We’ll go into more detail in a future article, but in short, adding 5-10% to the size of your factory turbo is a good safe bet to (once again) add airflow, lower EGT, and increase power without running into issues that are a detriment to long term reliability.

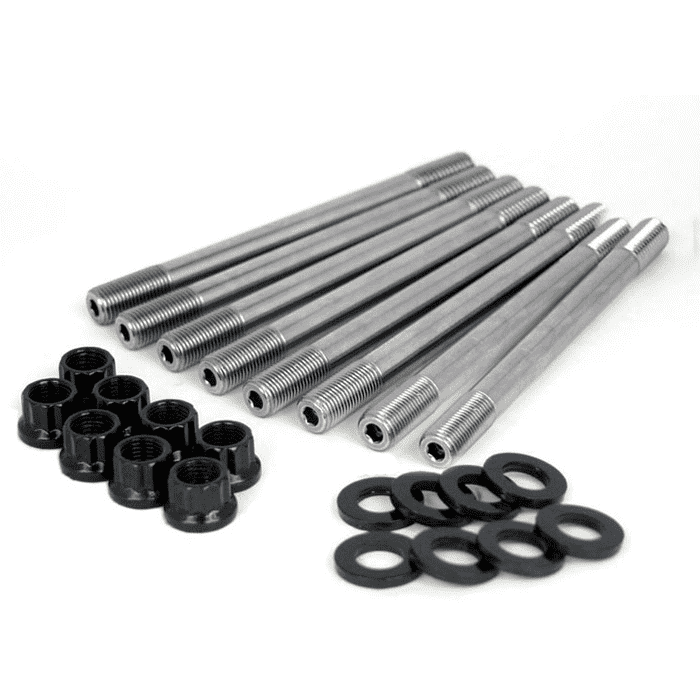

HEAD STUDS: Once you get beyond the basics of an intake/exhaust/tune you need to make some reinforcements to your truck before you attempt to add any more power. The stock head bolts on your truck only have so much holding power, especially if you have a 6.0 Ford. Once you add more power, the increased cylinder pressure can actually stretch the stock fasteners, cause the head to lift slightly, and you’ll wind up with a head gasket failure. You’ve likely heard about adding “studs” when talking about diesels, and what it means is you’ll replace the stock head bolts with a stronger stud which can keep the cylinder head clamped to the block and your truck on the road. Yes, it is an investment, and no, studs don’t add power by themselves, but they do go a long way to increasing the reliability of your pickup.

FLUIDS AND FILTRATION: When talking about adding power, fluids are often one of the least talked about things, but you might be surprised to learn that a quality synthetic fluid can actually reduce enough friction to free up some horsepower at the same time a good fluid will reduce wear and protects your engine, transmission, transfer case, and differentials for many miles to come.

Oil can break down from heat, regardless of its quality, so keeping the fluids cool is a number one priority. The most common cause of failure in an automatic trans is overheated fluid, so the most commonly monitored oil temp is for the transmission. The harder you work a trans and the more power you feed through it will lead to an increase in fluid temp, so a simple upgrade that will increase reliability is a larger and more efficient cooler. Just like an intercooler, a better trans cooler will remove more heat from the fluid, which means a longer life from your transmission. By simply changing to a better Mishimoto cooler, a 20˚F drop in fluid temperature can be reached.

Just as important as the fluid itself is the maintenance interval, and the filter which keeps the oil clean. Regularly scheduled oil and filter changes for all the lubricated systems are a very important aspect of owning a truck. By visiting the Maintenance and Filters tab of DPP, you can find all the necessities for keeping your specific rig on the road.

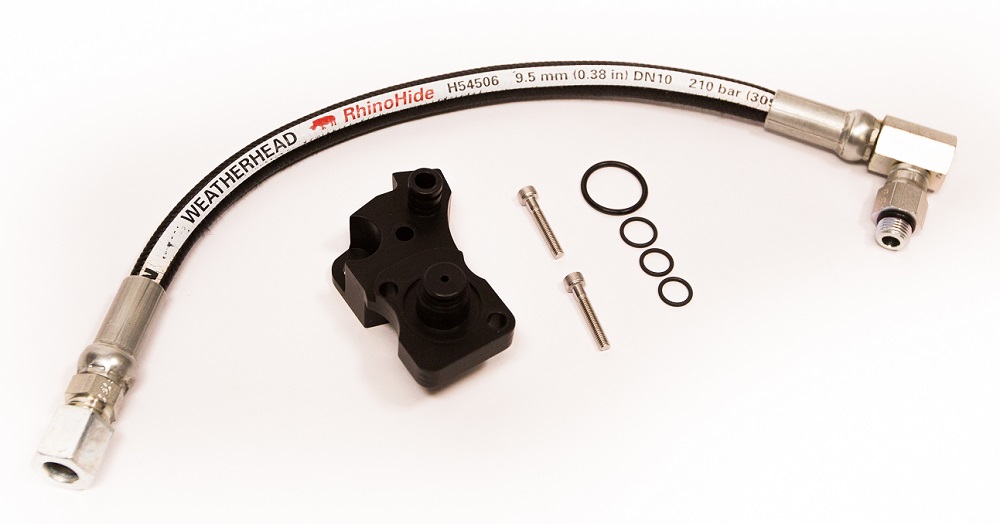

FUEL: Since the Diesel engine runs off fuel, no discussion about power and reliability can be complete without talking about the fuel system at least once. Over the lifetime of an average truck, 9,000 gallons or more of fuel will be pumped through the system, and with it will come a lot of contamination and water. It’s recommended to change your fuel filter at least every 10,000 miles to keep your engine happy, and certain trucks with the CP4 injection pump (LML Duramax and 6.7 Powerstroke) are very sensitive to any amount of dirt or water in the fuel. When the CP4 fails, it can lead to a Chernobyl like chain reaction that takes out the entire fuel system, since the debris from the failed pump will enter the high-pressure lines, fuel rail, injectors, return line, and tank. A shop will charge between 7 and 10 thousand bucks to replace all the parts and get your rig back on the road, so any preventative measure will save you a ton. A disaster prevention kit won’t stop your CP4 from failing, but what it will do is keep the rest of your fuel system safe from the fallout, which is very cheap insurance.

Rather than mess around waiting for the CP4 to fail, why not just replace it with a more reliable CP3? Companies like Industrial Injection offer a CP3 conversion kit which will eliminate the possibility of a pump failure, and you can even combine it with a larger capacity pump to boost your power potential at the same time as it increases reliability.

Powerful and Reliable

When it comes to adding power, it doesn’t have to come at the expense of reliability, and vice-versa. There are plenty of parts out there that will do both, and those are usually the smartest upgrades. Anything that will increase airflow efficiency, lower EGT, or make your engine run cooler and cleaner is a win in my book, since more horsepower and fuel efficiency is usually the much-welcomed side-effect. For the budget conscious crowd, an intake, exhaust, and tune will be the perfect pairing of power and reliability and gets you the most bang for your buck, but you don’t have to stop there. How far you push your truck is totally up to you, and there’s no reason a 600hp truck can’t be driven and worked hard every single day and have very little down time. It’s all about understanding the upgrades you need and taking care of your equipment. If you get this formula figured out, you will have very little trade-offs when building your diesel.

Hello,

Do you have any plans for products for the Jeep Gladiator ecodiesel?

Thanks

Hi there, Scott. We currently have a select few number of products for the Gladiator EcoDiesel, but you’re right, we haven’t built out a full-blown section for them yet, but I promise, its on the to-do list. As you know, I’m sure, Jeeps have a HUGE selection of products available for them, so we want to make sure that when we start creating the sections for the Gladiator, we have a nice assortment. That said, just because the products aren’t on our site doesn’t mean we don’t have access to them necessarily. Further, our sister company, Offroad Power Products, does currently have a wide selection of upgrades and I would recommend checking them out, as well. Here’s a link to that website: https://offroadpowerproducts.com/