Written By: L.T. Tolman

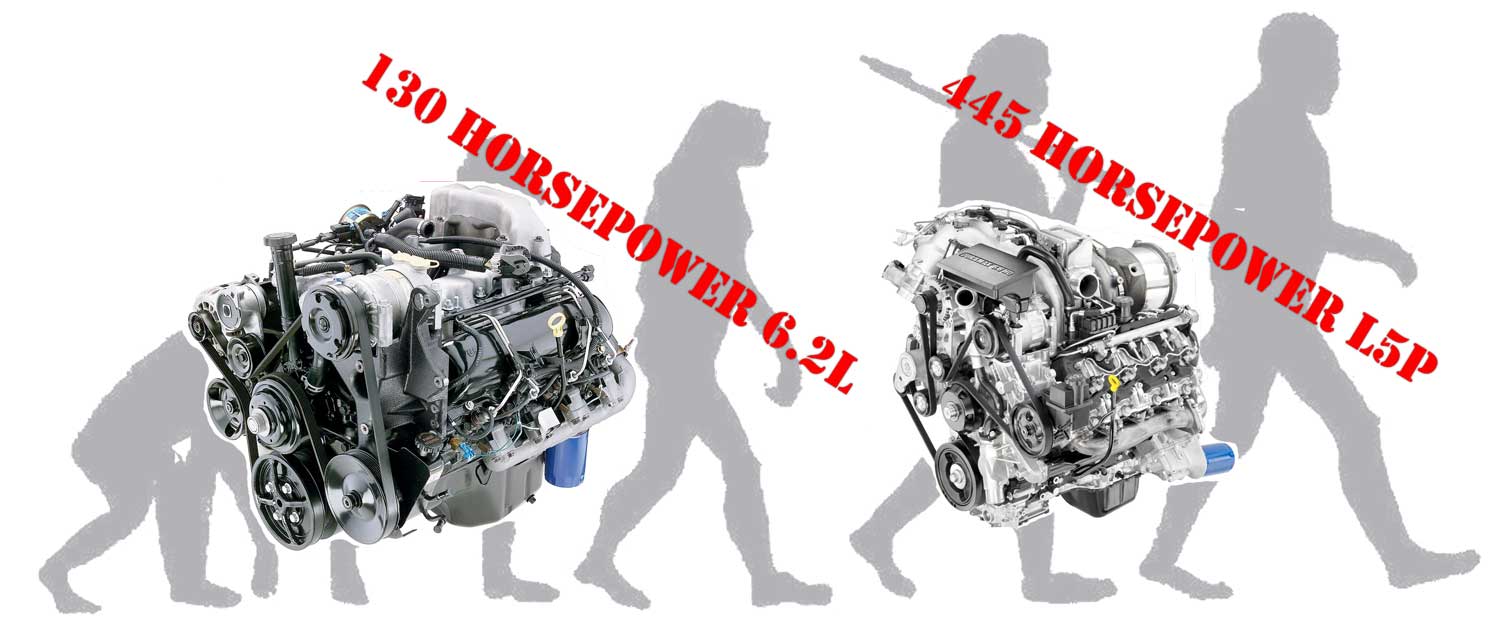

We’re in the middle of a three-part journey which takes a deep dive into the most popular late model diesel powerplants used in pickup trucks, and todays subject will be the various engines used by GM over the last 25 years. While Dodge relied on the inline six-cylinder Cummins to power their workhorses, GM went another route, added two more cylinders, sticking with a traditional V8 design. Over the last quarter century GM has used seven different V8 diesels, so let’s buckle up and get started.

GM 6.5 1992-2000

In the early 1990’s GM saw the need for a more fuel-efficient truck engine. At the time, the most popular option was the TBI 350 gas engines, and they were making around 190hp and could (under ideal conditions) achieve roughly 17 MPG. On the opposite end of the spectrum was the massive 7.4-liter 454 V8 which was much more powerful, but also thirstier, with some drivers getting a best of 12mpg unladen, and 8 when towing. To fill the gap in their lineup, GM introduced the 6.5 diesel in 1992, which was a slightly updated version of the 6.2 diesel that had been around since 1982. The 6.5 was the first diesel engine (in a pickup truck) to come fitted with electronic fuel injection, although the 6.5 used indirect rather than direct injection. The 6.5 came in both naturally aspirated and turbocharged trim, with the former making 155hp and 340 lb.ft of torque, and the latter coming in at 215hp and 440 lb.ft of torque. When combined with the proper gear ratio, the 6.5 could knock down an impressive 21 MPG, while still having enough torque to compete head to head with the Cummins engines of the era.

Though it was never had any real performance potential, the 6.5 is reliable. The most common issue revolves around the PMD or Pump Mounted Driver which control the injection pump. Because its an electronic device mounted directly to the pump, it easily gets heat soaked, and can internally fail, which will leave you stranded with a truck that won’t run. You can relocate the PMD to the firewall away from the source of heat, and it will last much longer. All you need to do is install a longer wiring harness, and you’re in business.

LB7 Duramax 2001-2004

In 2001, GM teamed up with Isuzu and brought another innovation to the diesel crowd and was first to market with a common-rail direct-injected diesel engine, the LB7. Like every Duramax that followed, it featured 6.6 liters (or 402 cubic inches) of displacement, a cast-iron block with aluminum heads, four valves per cylinder, and a single turbocharger mounted high in the center of the engine. For fueling duties, GM turned to Bosch, and implemented the CP3 high pressure injection pump, which was driven by a gear and mounted in the front of the lifter valley to put out a max of 23,000 psi. In 2001, the LB7 put out 235hp and 500 pounds of torque, thanks in part to a 17.5:1 compression ratio, but by 2004 those figures grew to 300hp and 520 lb.ft. The turbocharging system on the LB7 is unique compared to all other models, as it uses a fixed-geometry wastegated IHI turbocharger.

Much like the earliest common-rail Cummins, the LB7 is known to have injector issues, and on average they’ll last around 150,000 miles. Visible signs of a failed injector include haze from the exhaust at idle, poor fuel mileage, rough running, and lack of power. The best way to determine which injectors are failing is to read the balance rates on a scan tool. The acceptable range is between -4.0 and +4.0 mm3 in park, and +/-6.0 in drive. If one cylinder is significantly outside the threshold, that injector likely needs to be replaced. Its always a good idea to replace all four on the same bank since the labor costs are fairly high, but an injector failure is also a good excuse to upgrade all eight at the same time with a mild performance set. A 60-horsepower injector is a good all-around choice you can drive every day and haul a trailer but will give you a nice boost in power so you can have some fun at the track as well.

LLY Duramax 2004.5-2006

Midway through 2004, the Duramax got its first makeover, as well as a new name. The LLY had a lot of similarities with the LB7, and the main differences include the addition of EGR and a newer variable geometry turbocharger, this time manufactured by Garrett. Power figures saw a slight jump to 310hp and 520 pounds of torque, but compression remained at 17.5:1 for ’04.5 to ’05.

2006 was a bit of an odd year, as you could buy both an LLY and the later LBZ. It’s unclear why certain trucks received each engine, but the ’06 LLY was different from the earlier versions. It got a slight drop in compression to 16.8:1 and a bump in torque, measuring in at 605 lb.ft. If you are looking at purchasing a 2006 truck, you’ll want to check the 8th digit of the VIN: if it’s a “2” you have an LLY, and if it’s a “D” you have the LBZ.

The LLY’s have a notorious problem for overheating, and it doesn’t have much to do with the cooling system, rather the air intake. The turbo mouthpiece is very restrictive, which causes the turbo to work harder, and raises EGT while towing, or even driving empty in summer weather. The higher combustion temperature gets transfered into the cooling system, but it can’t extract the heat fast enough, so the engine gets too hot. The solution is to steal an intake horn from an LBZ (which is much larger inside) or purchase an aftermarket high flow elbow like the S&B Turbo Inlet which will keep those EGTs and coolant temp low and give a nice bump in power at the same time.

LBZ Duramax 2006-2007

The LBZ is considered by Chevy guys to be the holy grail of diesels, as it was the most powerful “pre-emissions” Duramax you could buy. Compression comes in at 16.8:1, and the CP3 was modified to produce a higher 26,000 psi. All this meant the LBZ could make 360hp at 3,200rpm and 650 pounds of torque at 1,600rpm. Even though we consider it to be pre-emissions, it still does have EGR and a DOC (a catalyst in the exhaust). By the time the LBZ had come out, the Duramax engine program was very well sorted out, and there are very few major issues to be found in terms of reliability, which is yet another reason why the LBZ is one of the most sought-after engines within the Bowtie family.

LMM Duramax 2008-2010

The LMM Duramax is almost identical to the LBZ from an internal standpoint, and power was only raised by +5hp and +10lb.ft, but the biggest difference was in the exhaust and emissions system. In 2008, all light duty diesels were under strict regulation and came equipped with a DPF to help keep emissions output in check. The particulate filter traps all the soot that would normally go into the atmosphere, and periodically that soot has to be burned off so the DPF doesn’t clog up. The LMM accomplishes this cleaning or “regeneration” procedure by using the late injection method, where on the exhaust stroke, the injectors are opened a second time, allowing fuel to be introduced into the exhaust system, which causes the filter to heat up and burn off the soot, much like a self-cleaning oven. With all that unburnt fuel making its way through the engine, there are some reports of the cylinder walls being stripped of lubrication which leads to excessive wear, low compression, and fuel diluting the engine oil, so if you are purchasing an LMM, be sure to keep an eye on the dip stick.

LML Duramax, 2011-2016

Oddly enough, the LML is the longest running version of the Duramax to date, with it being used over a 5-model year span. The emission system got another round of upgrades as well, and this time GM used a 9th injector mounted in the exhaust to supply fuel for DPF regeneration, which would eliminate the problem of oil dilution and scuffed cylinder walls. In addition, a new emission device called SCR or selective catalyst reduction was mounted in the exhaust and uses Diesel Exhaust Fluid to cause a chemical reaction and break down the harmful NOx compounds. Even with all the emission components, the LML was the most powerful Duramax to date, with ratings of 397hp and 765lb.ft. of torque. The compression ratio was dropped to 16.0:1, and the other major difference between the LML and all previous models is use of the newer Bosch CP4 injection pump, which could operate at higher pressure (up to 30,000psi). Unfortunately, this new pump was the downfall of many LMLs.

There are several causes, but the main problem with the CP4 boils down to lack of lubrication from modern ultra-low sulfur fuels. Metal parts are constantly rubbing against each other inside the pump, with fuel being the only lubricant. The hardened steel parts can cause the softer aluminum to turn into fine shavings, which will cause further wear on the inside of the CP4, and the pump will eventually lose pressure. That alone will leave you stranded, but sadly that’s not all that will go wrong. Once those metal shavings are in your fuel pump, they will be sent into your injectors, taking them out as well, adding thousands to your repair bill. The contamination eventually will make its way into the fuel return lines and the tank, making a complete replacement and cleanout of your fuel system necessary.

If you have an LML, the first preventative measure is to run an additive in your fuel which increases lubricity, like Everyday Diesel Treatment from Hotshot’s Secret. This will provide the missing lubricity to ULSD fuels, but will also keep your fuel system clean, and add some power and fuel economy as well. The second thing you can do to help your LML is to install a lift pump with air and water separation, like a FASS Titanium Signature Series. By removing the air from the fuel, it will be able to better lubricate the pump, and by feeding the CP4 with pressurized fuel rather than making if draw from the tank, its workload is reduced, which increases pump life. But even with all the preventative steps taken, there is still a risk of failure with a CP4 in place.

The end-all fix on an LML is to replace the injection pump with the earlier and more robust CP3. Since the design of the older pump is quite a bit different, you’ll need an installation kit like the Fleece CP3 conversion which comes with the pump mount, new high-pressure lines, hardware, and rubber feed lines. A stock CP3 pump will be much more reliable out of the box, but won’t do anything for performance, so while you’re in there, it makes sense to upgrade to a modified pump that will flow more fuel at higher RPM than stock, like the Fleece CP3K which won’t defuel over 3,000 rpm like the stock pump does.

L5P Duramax, 2017-present

Basically, GM took everything they learned over the last 15 years, threw out the old blueprints, and started with a clean sheet, and the resulting L5P is the most powerful Duramax ever, producing 445hp and 910 pounds of torque. Several notable changes include moving the turbo closer to the center of the engine and switching suppliers to Denso for the injection pump (HP4) and injectors. Borg Warner now supplies the turbo, which uses an electric motor to control the vanes instead of oil pressure like on all older generations. And after 15 years, GM finally learned their lesson and equipped the L5P with a lift pump.

Since the L5P is so new (and well-engineered) there haven’t been many major issues, other than the odd sensor failure. The best part of the new engine is the tuning potential is very high, with leading shops like Calibrated Power being able to safely extract 550rwhp with a TUNE ONLY, which is a significant milestone.

Fixes for any Duramax

While each generation has its own quirks, there are a few issues which are common across the board. Luckily the aftermarket has stepped up and offers many different solutions. First, from 2001 to 2016, no Duramax was equipped with a lift pump. While the CP3 doesn’t fail like the CP4, it can still benefit from having a lift pump, and if you are planning on running a higher power tune setting, a lift pump is necessary to deliver enough fuel to the injection pump to support the higher power demand of a hot tune. Usually, anything over a +150hp tune requires a lift pump, but even bone stock trucks can benefit from the cleaner, air-free fuel a lift pump offers.

The water pump on the Duramax is driven by a gear that’s pressed onto a small steel shaft. Over time, that gear can loosen up, allowing the impeller to damage the housing it sits in, and causes overheating. Welded water pumps are an inexpensive upgrade that will bolt right in place of the original, and prevent the issue from happening again, keeping your Duramax running cool for years to come.

A choice to make

Out of the seven available GM diesel engines, it might be hard to determine which is right for you. The older models are more affordable and less powerful but also carry less restrictive emission regulations, allowing much more freedom to turn up the power. The newer trucks look more stylish but carry a higher price tag which can eat into your modification budget. No matter which version of Duramax you choose, you’ll have a great multipurpose truck that can be driven every day, tow a lot of weight, get good fuel mileage, and if built right, take down a sportscar at the drag strip. There are plenty of power upgrades, and its just as easy to add another 100 horses as it is to add another thousand. It’s just a simple matter of picking your poison and opening up that checkbook.

I’ve recently bought a 2011 Duramax and my injector pump went out a month later the information I read help a lot it’s now in the shop getting replace I’ve been seriously thinking of installing a lift pump would this help the injector pump

Hi there and thanks for taking the time to read our article. Adding an inline lift pump with filters, such as the AirDog II-4G (https://www.dieselpowerproducts.com/p-15498-pureflow-airdog-ii-4g-a6spbc260-100-gph-air-fuel-separation-system-11-14-66l-gm-duramax-lml.aspx) or FASS Titanium (https://www.dieselpowerproducts.com/fass-ts-c11-100g-fuel-lift-pump-gm-lml) would help with the life of your injection pump for two reasons: consistent fuel delivery feeding the CP4 and clean, water and debris free fuel feeding the pump. Both of these are known to cause CP4 failure. Historically, the CP4’s have proven to not be as reliable as the previously used CP3’s that Chevy had on their Duramax engines from 2001-2010 so some will go as far as retrofitting the truck back to a CP3 with various kits, such as this one from Fleece Performance:

https://www.dieselpowerproducts.com/p-fleece-performance-emissions-compliant-cp3-conversion-kit-11-16-gm-66l-duramax-lml

I worked at the Duramax engine plant for over 17 years. Honestly, iv never worked at a job where I was treated so well. The employees were happy and it showed in their product. It was the Japanese custom that made us feel like a family. It is a joint venture between Isuzu and GM with GM owning the majority of the shares. Just like anything in life there are going to be a few bad engines that make it through final test and quality. I would never let that discourage me from buying another one. Banks engineering from my hometown of Pomona, Ca. have some record breaking duramax builds over the the years. Not to mention like the article said, the aftermarket scene goes as long as you can afford and then some. So which ever engine you own, whether in a hotrod, truck, plane, Military JLTV, or marine application. Just know your apart of a unique family of enthusiasts…..

This is some great background information on the plant itself, thank you so much!